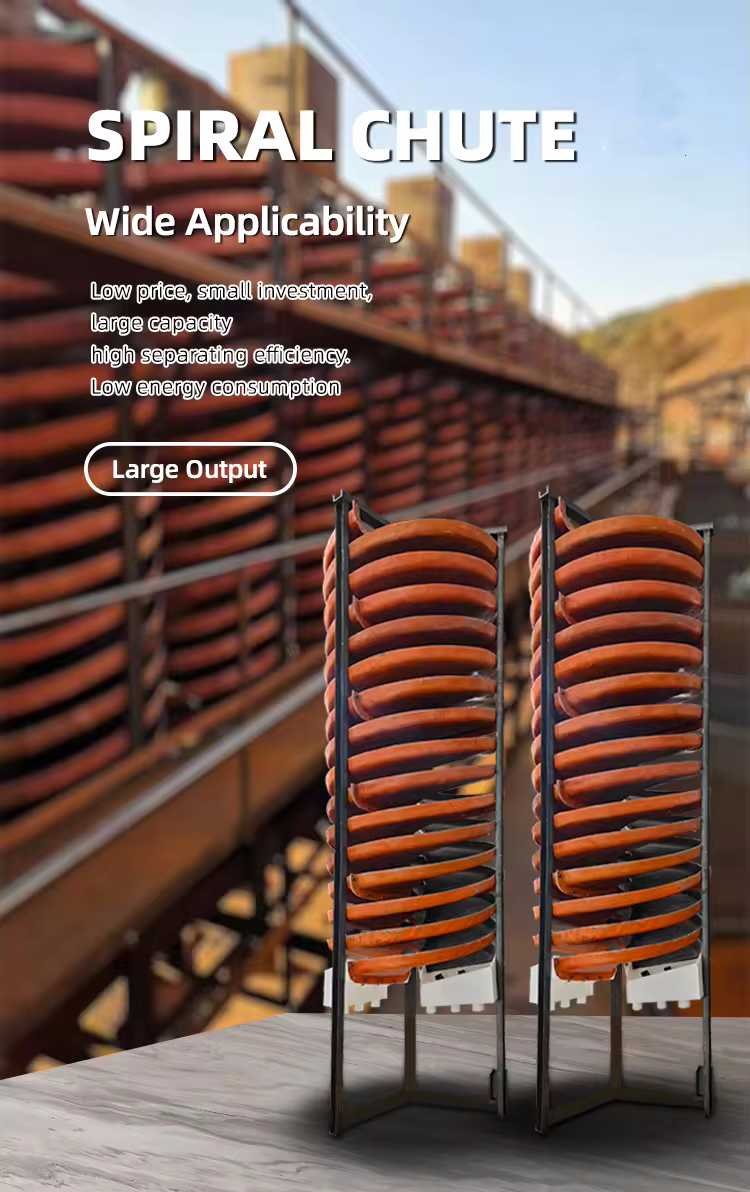

Gravity Spiral Chute

Description

The greatest concentrating equipment, particularly for concentrating sand ore in beaches, rivers, seashores, and streams, is our company’s gravity spiral chute separator. It is a scientific product with concentrating experience. Additionally, it has been used to enrich low-grade mineral such as coal, iron, tin, chromite, ilmenite, tungsten, zinc, tantalum-niobium, gold, coal, monazite, rutile, zircon, and others with fine grain sizes of 0.3–4 mm. the non-metallic minerals with sufficiently different specific gravities.

The product’s advantages are light weight, moisture resistance, anti-rust, anti-corrosion, and noiseless; it is constructed of fiberglass lined with wear-resistant resin and cover emery. It is also appropriately suited for a range of feeding particle sizes and grades. It’s the new, incredibly efficient equipment, the advanced level domestically.

Water flow, gravity, inertial centrifugation, and friction are the forces that drive the Mineral Gravity Spiral Chute Separator. After being pumped to the top of the spiral, the slurry enters a feed distributor that divides the feed among the spiral chutes uniformly. It functions because of the spiral’s form and construction in conjunction with gravitational acceleration. Grain size and density, as well as shape to a lesser extent, begin to settle and sort as the slurry moves along the spiraling course down the spiral. The highest density particles travel inside the spiral, whereas low density particles are carried by the majority of the water towards its outside.

2). High recovery, high efficiency, and precise separation

3). Non-required power

4). Light in weight, anti corrosion, rust and wear resistant

5). Simple installation and Minimal maintenance requirements

6). Low operating costs and long working life

7). Reliable running with minimal operator attention

8). Strong adaptability to fluctuation of feeding amount, density, size and grade

9). The surface of emery forms strong friction; the concentration effect surpasses plastic surface

Product Specification

Model | 5LL-2000 | 5LL-1500 | 5LL-1200 | 5LL-900 | 5LL-600 | 5LL-400 | |

Outside Dia. (mm) | 2000 | 1500 | 1200 | 900 | 600 | 400 | |

Pitch (mm) | 1200 | 800,680,540 | 720,540,360 | 660,540,400 | 450,360,270 | 240,180 | |

Lateral slope | 9° | 9° | 9° | 9° | 9° | 9° | |

External size | Length (mm) | 2300 | 1560 | 1360 | 1060 | 700 | 460 |

Width (mm) | 2300 | 1560 | 1360 | 1060 | 700 | 460 | |

Height (mm) | 6500 | 5230 | 5230 | 4000 | 2600 | 1500 | |

Starts/Turns per column | 4-2 | 4-2 | 4-2 | 4-2 | 2 | 2 | |

Feeding size (mm) | 4-0.04 | 0.8-0.037 | 0.3-0.03 | 0.3-0.03 | 0.2-0.02 | 0.2-0.02 | |

Feeding density (%) | 20-45 | 30-60 | 25-55 | 25-55 | 25-55 | 25-55 | |

Capacity (t/h) | 12-10 | 8-6 | 4-6 | 2-3 | 0.8-1.2 | 0.15-0.2 | |

Weight (KG) | 1100 | 800 | 600 | 400 | 150 | 50 | |