Indian Installed Spiral Chute Separator for Silica Sand: Enhancing Efficiency and Quality

The spiral chute separator is a vital tool in the mining and mineral processing industries, designed to effectively separate particles based on differences in their density. Utilizing the force of gravity, these devices are particularly efficient in isolating materials of varying densities, which makes them indispensable for mineral separation tasks. The principle of operation is straightforward: as the slurry containing the mineral particles is fed into the spiral chute, the gravitational force acts on the particles, causing the denser materials to move towards the inner edge of the spiral while the lighter ones are pushed towards the outer edge. This natural stratification allows for the efficient segregation of different mineral components.

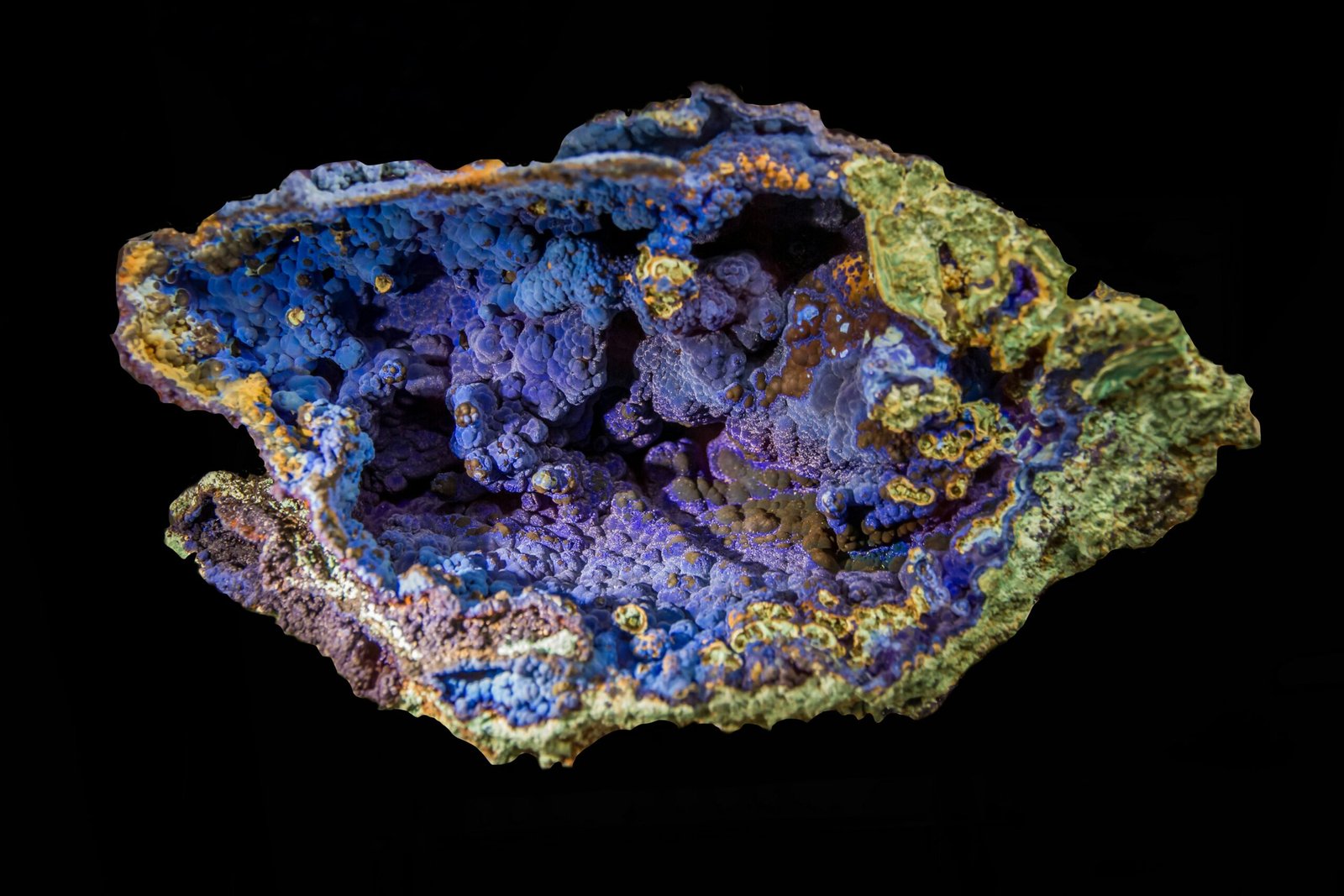

In the context of silica sand processing, the installation of a spiral chute separator becomes especially significant. India, with its burgeoning industries in glass manufacturing, construction, and electronics, has witnessed a rising demand for high-purity silica sand. The spiral chute separator plays a crucial role in meeting this demand by ensuring that the silica sand is of the highest quality, free from impurities such as heavy minerals and other contaminants. The ability to produce high-purity silica sand not only enhances product quality but also supports the stringent requirements of these advanced industries.

Moreover, spiral chute separators offer notable environmental benefits compared to other separation methods. They significantly reduce the need for chemical additives, which are often required in other beneficiation processes. This reduction in chemical usage not only lowers operational costs but also minimizes environmental pollution. Additionally, spiral chute separators are known for their low energy consumption, making them a more sustainable option in mineral processing. The lower energy requirement translates to reduced operational expenses and a smaller carbon footprint, aligning with global efforts towards greener industrial practices.

Case Study: Installation and Operational Benefits of the Spiral Chute Separator in India

The installation of the spiral chute separator in an Indian silica sand processing plant marked a significant advancement in the industry’s pursuit of efficiency and quality. The process began with a thorough site assessment to determine the optimal placement for the separator. Engineers conducted detailed analyses of the plant’s layout and silica sand flow patterns, ensuring that the separator would integrate seamlessly with existing systems.

One of the primary challenges during the installation was accommodating the spiral chute within the plant’s confined space. This required precise measurements and custom modifications to the chute’s design. Despite these hurdles, the installation team, comprising experienced engineers and technicians, successfully positioned the separator without disrupting ongoing operations.

Post-installation, the benefits of the spiral chute separator became immediately apparent. The most notable improvement was the enhanced efficiency in silica sand separation. The spiral chute’s design allows for a more refined separation process, resulting in higher product purity. This was particularly beneficial for the plant, as it led to a superior quality of silica sand, meeting stringent industry standards.

Additionally, the operational costs of the plant saw a significant reduction. The spiral chute separator’s low maintenance requirements and energy-efficient operation contributed to lower overall expenses. Plant managers reported a noticeable decrease in downtime, further boosting productivity and profitability.

Feedback from key stakeholders was overwhelmingly positive. “The installation of the spiral chute separator has been a game-changer for our plant,” remarked one plant manager. “We have seen a substantial improvement in the quality of our silica sand, and the reduced operational costs have positively impacted our bottom line.”

The success of this installation highlights the potential for wider adoption of spiral chute separators across other silica sand processing facilities in India. As more plants recognize the long-term benefits—such as increased efficiency, reduced costs, and improved product quality—industry-wide implementation of this technology is likely to grow, driving the sector towards greater sustainability and profitability.