Limestone Extraction Method: A Complete 2025 Guide

Limestone is one of the most important raw materials in construction, cement production, and industrial processes. This guide explores the step-by-step process of limestone extraction and highlights how ORO Mineral is revolutionizing quarrying and mineral processing with innovative equipment and intelligent technology.

Importance of Limestone

Limestone is a sedimentary rock primarily composed of calcium carbonate (CaCO₃). It is widely used in:

- Cement production – the backbone of construction

- Steel industry – as a fluxing agent

- Soil conditioning – to neutralize acidity

- Water treatment – as a filtration medium

- Glass manufacturing – as a key ingredient

Limestone Extraction Methods

The two primary methods for limestone extraction are:

- Open-Pit Quarrying: The most common method, involving removing overburden and cutting limestone blocks.

- Underground Mining: Used where surface access is limited, requiring room-and-pillar or longwall techniques.

Modern quarries often use a combination of mechanical cutting, drilling, blasting, and crushing to optimize productivity.

ORO Mineral: Advanced Equipment for Quarrying

ORO Mineral is a large-scale intelligent mineral processing, screening, and sand washing equipment manufacturer integrating R&D, production, and sales. Since 2014, they have contributed significantly to mineral screening, solid waste recovery, beneficiation, and separation.

They continuously innovate to improve technology, develop new equipment, and upgrade services for the global mining industry.

ORO Mineral’s Core Products:

Step-by-Step Limestone Extraction Process

1. Geological Survey & Resource Assessment

Experts conduct surveys and core drilling to evaluate the deposit’s quality, thickness, and economic viability.

2. Site Preparation & Overburden Removal

Topsoil and overburden are removed to expose the limestone bed. This material is often stored for later site reclamation.

3. Drilling

Blast holes are drilled into the limestone bench following a precise pattern for efficient rock fragmentation.

4. Blasting

Controlled blasting breaks the rock into manageable pieces while minimizing vibration and environmental impact.

5. Excavation & Loading

Excavators or front-end loaders collect the fragmented limestone and load it into haul trucks.

6. Crushing & Screening

Primary crushers reduce large rocks to smaller sizes, followed by screening to separate various grades of limestone.

7. Washing & Beneficiation

Washing machines remove impurities like clay and dust, producing clean, high-quality limestone suitable for industrial use.

Key Equipment Used

- Excavators and Loaders: For material handling

- Drilling Rigs: For precision blast hole drilling

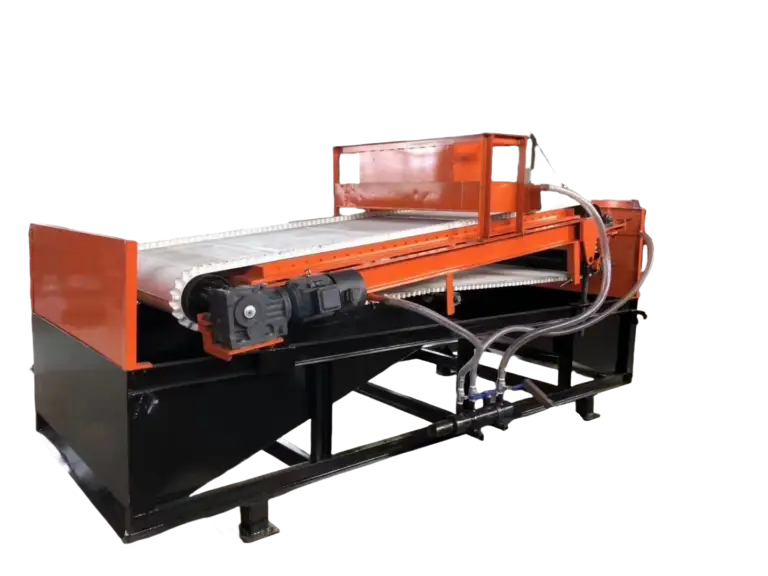

- Crushers and Screens: For size reduction and sorting

- Sand Washing Machines: To remove impurities and enhance quality

- Magnetic & Eddy Current Separators: For removing unwanted metallic impurities

Environmental Considerations

Modern limestone mining focuses on sustainability and environmental protection. Key measures include:

- Dust control systems to minimize air pollution

- Water recycling in washing operations

- Noise reduction techniques in blasting

- Land reclamation plans for post-mining use

- Energy-efficient equipment to lower carbon emissions

Summary Table

| Stage | Purpose | Importance |

|---|---|---|

| Geological Survey | Identify deposit location and quality | Ensures economic viability |

| Drilling & Blasting | Break limestone into workable sizes | Optimizes production efficiency |

| Crushing & Screening | Produce graded limestone | Meets industry specifications |

| Washing & Beneficiation | Remove impurities | Improves quality for cement & industry |

| Environmental Management | Minimize impact | Ensures sustainable operations |

FAQs & References

1. What is the most common limestone extraction method?

Open-pit quarrying is the most common method due to its efficiency and cost-effectiveness.

2. How is environmental impact minimized?

By implementing dust suppression, water recycling, controlled blasting, and post-mining land reclamation plans.

References: