What Is Magnetic Separation Equipment?

Understanding magnetic separation equipment is essential for anyone involved in mineral processing, recycling, metallurgy, and industrial waste recovery. In 2025, global demand for efficient, automated separation technology continues to rise — and magnetic separation equipment plays a crucial role in improving extraction efficiency, reducing waste, and increasing product purity.

Table of Contents

- What Is Magnetic Separation Equipment?

- How Magnetic Separation Equipment Works

- Types of Magnetic Separation Equipment

- Industrial Applications

- Benefits of Using Magnetic Separation Equipment

- Summary Comparison Table

- ORO Mineral Co., Ltd. — Company Spotlight

- Featured Products

- Frequently Asked Questions

- References

What Is Magnetic Separation Equipment?

Magnetic separation equipment refers to a specialized category of industrial machinery designed to separate magnetic materials from non-magnetic materials. These systems rely on high-intensity magnetic fields to extract ferrous and paramagnetic particles from ores, aggregates, metals, plastics, and recycled waste streams.

In modern processing plants, magnetic separation equipment is essential for improving product purity, recovering valuable minerals, and ensuring consistent production quality. Whether used for mining iron ore or removing metallic contaminants from sand, grains, or plastics, magnetic separation equipment has become a cornerstone of industrial efficiency.

How Magnetic Separation Equipment Works

At its core, magnetic separation equipment operates by generating a magnetic field strong enough to attract magnetic particles. These particles are pulled toward the magnetic source while non-magnetic materials continue moving along the conveyor or processing stream.

1. Magnetic Attraction

Magnetic minerals such as magnetite, ilmenite, and hematite respond strongly to magnetic fields. When processed with magnetic separation equipment, these minerals are drawn toward the magnetic surface.

2. Mechanical Separation

Non-magnetic materials follow the natural path of gravity or conveyor movement, while magnetic materials attach to the magnet until discharged at a separate outlet.

3. Adjustable Magnetic Field Strength

Modern magnetic separation equipment includes adjustable magnetic intensity, allowing operators to target specific materials and achieve higher accuracy.

Types of Magnetic Separation Equipment

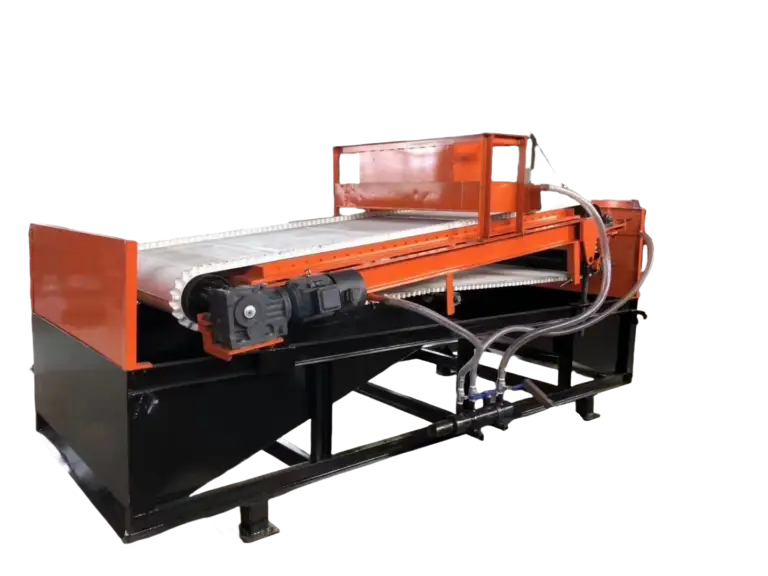

1. Belt Magnetic Separator

A belt magnetic separator uses a moving conveyor and a high-intensity magnetic roller to continuously extract iron-containing particles. This type of magnetic separation equipment is widely used for bulk material handling and mineral beneficiation.

2. Dry Electromagnetic Separator

A dry electromagnetic separator is designed for dry mineral processing. It uses strong electromagnetic coils to remove magnetic metal particles from granular materials. This magnetic separation equipment is particularly common in mining, smelting, and ceramics.

3. Eddy Current Separator

Although not magnetic in the traditional sense, eddy current separators use rapidly rotating magnetic drums to repel non-ferrous metals such as aluminum and copper. They complement magnetic separation equipment by removing non-ferrous contaminants.

Industrial Applications of Magnetic Separation Equipment

1. Mining and Mineral Processing

In mineral processing plants, magnetic separation equipment is essential for upgrading low-grade ores and improving concentration efficiency.

2. Recycling and Waste Management

Magnetic systems help remove metallic contaminants from plastics, paper, and municipal waste, improving recovery value and reducing contamination.

3. Food and Pharmaceutical Industries

Ensuring purity is critical. Magnetic separation equipment removes metal fragments to maintain strict safety standards.

4. Metallurgy and Foundries

Magnetic separation helps recover reusable metal materials and purify casting sands.

Benefits of Using Magnetic Separation Equipment

- Improves mineral recovery efficiency

- Reduces processing waste

- Enhances product purity

- Increases overall production efficiency

- Reduces equipment wear by removing metal contaminants

- Supports environmentally friendly resource recovery

Summary Comparison Table

| Equipment Type | Main Function | Best for | Key Advantage |

|---|---|---|---|

| Belt Magnetic Separator | Continuous removal of ferrous materials | Mining, processing plants | High throughput & automation |

| Dry Electromagnetic Separator | High-intensity magnetic extraction | Dry mineral processing | Precise separation |

| Eddy Current Separator | Non-ferrous metal removal | Recycling centers | Excellent for aluminum & copper recovery |

ORO Mineral Co., Ltd. — Company Spotlight

ORO Mineral Co., Ltd. is a large-scale intelligent manufacturer of mineral processing, screening, and sand washing equipment. Since 2014, ORO Mineral has contributed extensively to global mineral screening, solid waste resource recovery, and industrial beneficiation systems.

Their continued commitment to innovation, R&D, and the development of advanced magnetic separation equipment allows them to provide cost-effective, high-efficiency solutions for mining and industrial clients.

Featured Magnetic Separation Equipment

1. 1.1kW Belt Magnetic Separator

A high-performance belt-type magnetic separation equipment designed for continuous iron removal in processing lines.

2. Dry Electromagnetic Separator

Ideal for high-precision mineral sorting, this dry electromagnetic separator delivers powerful performance.

3. Eddy Current Separator Machine

Advanced non-ferrous separation system used widely in recycling and metal recovery industries.

Frequently Asked Questions

1. What is magnetic separation equipment used for?

It is used to remove magnetic and metallic contaminants from materials and improve mineral processing efficiency.

2. Is magnetic separation equipment necessary for recycling?

Yes. It helps recover valuable metals and ensures cleaner recycled material streams.

3. Can magnetic separation equipment process wet and dry materials?

Yes. Different equipment types support wet, dry, bulk, and fine material separation.

References