5 Methods to Separate Iron and Steel: The Complete Industrial Guide

In the expansive worlds of recycling, mineral processing, and materials engineering, the ability to efficiently separate materials is the cornerstone of profitability and sustainability. Among the most critical tasks is the recovery of ferrous metals. Whether you are processing scrap for a foundry or refining ore in a mine, understanding how to separate iron and steel from mixed waste streams—and distinguishing them from one another—is vital.

Iron and steel are often grouped together as “ferrous metals” due to their magnetic properties, but separating them requires a nuanced approach depending on the context. Sometimes the goal is to extract both from a pile of rubble; other times, the goal is to separate cast iron from low-carbon steel to ensure product purity. This guide explores the five most effective methods used in 2026 to separate iron and steel, ranging from traditional magnetism to advanced sensor-based sorting.

- 1. Understanding the Challenge: Iron vs. Steel

- 2. Method 1: Magnetic Separation (The Industry Standard)

- 3. Featured Solution: ORO Mineral Co., Ltd.

- 4. Method 2: Gravity Separation (Density-Based)

- 5. Method 3: Eddy Current Separation (Indirect Sorting)

- 6. Method 4: Sensor-Based Sorting (XRF and LIBS)

- 7. Method 5: Heavy Media Separation (HMS)

- 8. Summary Comparison Table

- 9. Frequently Asked Questions

- 10. Conclusion

1. Understanding the Challenge: Iron vs. Steel

Before diving into the machinery, it is essential to clarify what we mean when we seek to separate iron and steel. In the broadest industrial sense, this often means separating ferrous metals (both iron and steel) from non-ferrous metals (like aluminum and copper) and non-metallic waste (like plastic and sand).

However, a more complex challenge lies in separating pure iron (or cast iron) from steel alloys. Steel is essentially an alloy of iron and carbon. Because both are magnetic and have similar densities, separating them requires precise techniques. Cast iron typically has a carbon content greater than 2%, making it more brittle and slightly less dense than steel, which has a carbon content of less than 2%. The methods below cover solutions for both extracting ferrous metals from mixtures and distinguishing between ferrous grades.

2. Method 1: Magnetic Separation (The Industry Standard)

The most common, cost-effective, and reliable way to separate iron and steel from a mixed waste stream is magnetic separation. Since both iron and most steels are ferromagnetic, they are strongly attracted to magnetic fields. This method is ubiquitous in recycling plants, mining operations, and food processing facilities.

How It Works

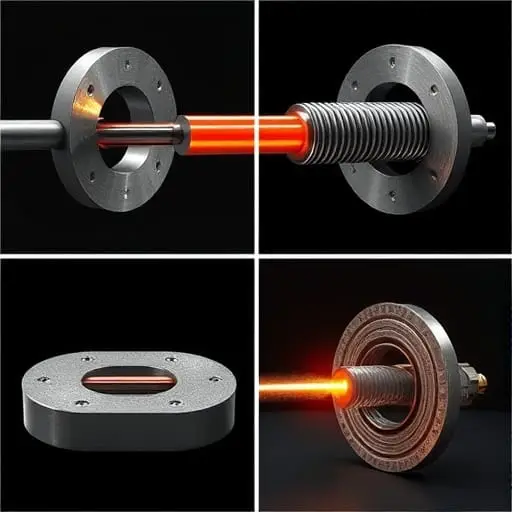

Magnetic separators utilize powerful permanent magnets or electromagnets to pull ferrous materials out of a moving stream of material. This typically occurs on a conveyor belt. As the mixed material moves along the belt, the non-magnetic material (plastic, wood, sand) falls off the end due to gravity. The iron and steel, however, adhere to the belt where the magnet is located and are carried to a separate discharge chute.

Types of Magnetic Separators

- Overband Magnets: Suspended above a conveyor belt, these lift iron and steel objects out of the burden.

- Magnetic Pulleys: The head pulley of the conveyor is magnetic, holding ferrous items to the belt longer than non-ferrous items.

- Drum Magnets: Ideal for high-volume flows, often used in mineral processing to recover iron ore.

In the context of ORO Mineral’s expertise, the 1.1kw Belt Magnetic Separator is a prime example of equipment designed to handle rugged industrial environments, effectively pulling ferrous contaminants or valuable scrap from aggregate and mining streams.

Featured Manufacturer: ORO Mineral Co., Ltd.

When implementing industrial separation systems, equipment reliability is paramount. ORO Mineral Co., Ltd. is a large-scale intelligent mineral processing, screening, and sand washing equipment manufacturer integrating R&D, production, and sales. Since 2014, ORO Mineral has made great contributions to every kind of mineral screening, solid waste resource recovery, beneficiation, washing, and separation, and has accumulated rich experience.

Whether you are looking to separate iron and steel from mining tailings or recycle construction waste, their portfolio offers specialized solutions:

3. Method 2: Gravity Separation (Density-Based)

While magnetism is king for bulk separation, gravity separation is the master of mineral processing. This method is particularly useful when you need to separate iron and steel particles (or iron ore) from lighter contaminants like silica, sand, or plastic, based on the principle of Specific Gravity.

The Principle

Iron and steel are significantly denser than most waste materials. Iron has a density of roughly 7.8 g/cm³, whereas sand is around 2.6 g/cm³. When suspended in water or subjected to centrifugal force, the heavier iron particles sink or move outward, while the lighter waste floats or stays central.

Equipment Spotlight: Spiral Chutes

The Gravity Spiral Chute Separator mentioned in ORO Mineral’s lineup is a classic tool for this. Slurry is fed into the top of a helical trough. As it spirals down, centrifugal force pushes the lighter waste particles to the outer edge of the stream, while the heavy iron or steel particles concentrate on the inner edge. This is highly effective for recovering fine iron particles from soil or sand mixtures.

4. Method 3: Eddy Current Separation (Indirect Sorting)

To effectively separate iron and steel, you sometimes need to remove everything else first. Eddy Current Separators (ECS) are technically designed to separate non-ferrous metals (like aluminum, copper, and brass) from non-metallic waste, but they play a crucial role in the ferrous separation ecosystem.

The Process

An ECS uses a rapidly rotating magnetic rotor inside a non-conductive shell. This rotation induces “eddy currents” in conductive metals like aluminum. These currents create a magnetic field that opposes the rotor’s field, literally repelling the aluminum and throwing it forward.

Role in Iron/Steel Separation

In a typical recycling line, an ECS is placed after the magnetic separator. First, the magnet removes the iron and steel. Then, the ECS kicks out the aluminum. The remaining material is non-metal waste. This multi-stage process ensures that the iron and steel fraction is pure and not contaminated with non-ferrous metals, increasing its market value. ORO Mineral’s Eddy Current Separator Machine is critical for facilities aiming for high-purity sorting.

5. Method 4: Sensor-Based Sorting (XRF and LIBS)

If your goal is to separate iron and steel from each other—specifically distinguishing between different grades of steel or separating cast iron from low-carbon steel—magnetism and gravity won’t work well, as both materials behave similarly. This is where advanced sensor technology steps in.

X-Ray Fluorescence (XRF)

XRF sensors bombard the material with X-rays, causing the elements in the metal to emit secondary fluorescent X-rays. Each element produces a unique signature. An automated system detects this signature and uses air jets to blow specific types of steel into different bins. This allows recyclers to separate stainless steel (which contains nickel and chromium) from standard carbon steel.

Laser-Induced Breakdown Spectroscopy (LIBS)

LIBS is even more precise. A high-energy laser hits the metal surface, creating a tiny plasma plume. A spectrometer analyzes the light emitted by this plasma to determine the exact chemical composition. This technology is incredibly fast and can sort aluminum alloys, but it is increasingly used to sort high-value steel scraps based on their specific alloy content.

6. Method 5: Heavy Media Separation (HMS)

Heavy Media Separation (HMS), also known as Sink-Float separation, is a robust industrial method used to separate iron and steel from non-ferrous automobile scrap (shredder residue) or to concentrate iron ore.

The Fluid Dynamics

In this process, the mixed material is submerged in a liquid (the “media”) with a specifically controlled density. The density of the media is set between the density of the two materials you wish to separate.

For example, to separate aluminum (density ~2.7) from steel (density ~7.8), you might use a media with a density of 3.0. The aluminum will float, and the steel will sink. While this is most commonly used to separate metals from non-metals, precise control of the media density (using ferrosilicon suspensions) can help segregate different grades of metallic ore or separate heavy cast iron blocks from lighter contaminants in a shredder output.

7. Summary Comparison Table

The following table summarizes the five methods, highlighting their primary mechanisms and best use cases for those looking to separate iron and steel.

| Method | Primary Force | Best Application | Equipment Example |

|---|---|---|---|

| Magnetic Separation | Magnetism | Extracting ferrous metals from mixed waste/ore. | Belt Magnetic Separator |

| Gravity Separation | Specific Gravity (Density) | Separating fine iron particles from sand/slag. | Spiral Chute Separator |

| Eddy Current | Conductivity / Repulsion | Purifying ferrous streams by removing non-ferrous metals. | Eddy Current Machine |

| Sensor Based (XRF/LIBS) | Chemical Composition | Distinguishing stainless steel from carbon steel; alloy sorting. | X-Ray Sorters |

| Heavy Media (HMS) | Buoyancy | Bulk separation of shredded scrap based on density. | Sink-Float Tanks |

8. Frequently Asked Questions

Q: Can magnets separate stainless steel from regular steel?

A: Not always. Austenitic stainless steel (like 304) is non-magnetic or very weakly magnetic, while regular carbon steel is strongly magnetic. Therefore, a standard magnetic separator will pick up the carbon steel and leave the stainless steel behind. However, ferritic stainless steels are magnetic, making separation via magnets difficult.

Q: How does ORO Mineral’s Spiral Concentrator help separate iron?

A: The Gravity Spiral Concentrator uses the weight difference between iron particles and silica (sand). As water washes the mixture down the spiral, the heavier iron stays close to the center, allowing it to be collected separately from the lighter sand which washes to the outside.

Q: Is it possible to separate cast iron from steel scrap?

A: Yes, but it is difficult. Because both are magnetic, you cannot use magnets. In manual yards, “Spark Testing” (grinding the metal to see the spark pattern) is used. In automated plants, density separation or advanced sensors (LIBS) are required because cast iron is slightly less dense and more brittle than steel.

Q: Why is it important to separate iron and steel in recycling?

A: Purity determines price. Steel mills require specific chemical compositions to melt new steel. If a batch of scrap steel is contaminated with too much copper (from electric motors) or aluminum, the resulting new steel will be weak or brittle. Proper separation ensures high-quality recycled materials.

10. Conclusion

The ability to separate iron and steel from waste streams is fundamental to the circular economy and the mining industry. While magnetic separation remains the workhorse for bulk extraction, achieving high-purity results often requires a multi-stage approach. By combining magnetic pulleys with gravity-based spiral chutes for fines, and employing eddy currents to clean the stream, operators can maximize recovery rates