5 Advantages of Using Magnets in Separation Processes

Table of Contents

- Introduction: What Is Magnetic Separation?

- Types of Magnetic Separators

- How Magnetic Separation Works

- Advantages of Using Magnets in Separation

- 4.1 High Efficiency

- 4.2 Versatility

- 4.3 Environmentally Friendly

- 4.4 Cost-Effective

- 4.5 Safety and Minimal Handling

- The Role of Dry Electromagnetic Separators in Industrial Applications

- Understanding the ORO Mineral Dry Electromagnetic Separator

- How to Choose the Right Magnetic Separator for Your Needs

- FAQs

- Conclusion

Introduction: What Is Magnetic Separation?

Magnetic separation is a widely used technique in various industries to separate magnetic materials from non-magnetic ones. By using powerful magnets, this process can efficiently extract valuable materials, remove contaminants, and enhance the quality of products. Magnetic separation is used in mining, recycling, food processing, and even in scientific research to achieve high purity and efficient material separation.

In this article, we will explore the advantages of using magnets in separation, the role of dry electromagnetic separators, and how these systems can benefit industrial operations. We will also take a closer look at the ORO Mineral Dry Electromagnetic Separator, a cutting-edge solution designed for high-performance separation.

Types of Magnetic Separators

Magnetic separators come in different types, each suited for specific applications. Below are the main types of magnetic separators:

- Wet Magnetic Separators: These separators use water or other liquids as a medium to separate magnetic materials from non-magnetic ones.

- Dry Magnetic Separators: These do not use any liquid and rely purely on the magnetic field for separation. Dry magnetic separators are commonly used for separating fine powders or materials that may be affected by water.

- Electromagnetic Separators: These separators use electromagnetic fields to generate powerful magnetic forces that can be controlled and adjusted. They are often used for industrial processes where high-intensity separation is required.

How Magnetic Separation Works

Magnetic separation works by using a magnetic field to attract and remove specific materials from a mixture. The key to this process is the magnetic properties of the materials involved. Some materials, like iron, nickel, and cobalt, are naturally magnetic and are attracted to magnetic fields. Others, like plastic, wood, and certain metals, are non-magnetic and do not react to the magnetic field.

In a typical magnetic separation process:

- Magnetic Field Generation: The separator generates a magnetic field using a magnet or electromagnet.

- Material Feed: The mixture of materials is fed into the separator, where the magnetic field captures the magnetic particles.

- Separation: Magnetic materials are pulled towards the magnet, while non-magnetic materials pass through unaffected.

- Collection: The separated materials are collected in separate containers for further processing.

Advantages of Using Magnets in Separation

Magnetic separation offers several advantages over traditional mechanical or chemical methods. Below are the key benefits of using magnets in separation processes:

4.1 High Efficiency

Magnetic separation is known for its high efficiency in separating materials. By using a magnet, you can quickly and effectively remove unwanted materials from a product or a material stream. In industrial applications, this leads to improved product quality and reduced contamination. The high separation efficiency also reduces the need for additional processing steps.

- Example: In mining, magnetic separators can efficiently extract valuable magnetic ores from large volumes of material, reducing processing costs and time.

4.2 Versatility

One of the most significant advantages of magnetic separation is its versatility. Magnets can be used to separate a wide range of materials, including:

- Ferrous materials (such as iron and steel)

- Non-ferrous metals

- Minerals and ores

- Plastic and wood (through induced magnetism)

- Food particles (for contamination removal)

This wide range of applications makes magnetic separation a valuable tool in many industries, from recycling to food production.

- Example: In the recycling industry, magnetic separation is used to extract metals from mixed waste, allowing for the recovery of valuable materials.

4.3 Environmentally Friendly

Magnetic separation is an environmentally friendly method of separating materials because it requires no chemicals, water, or other environmentally harmful substances. This makes it an ideal option for industries looking to reduce their environmental footprint and comply with strict environmental regulations.

- Example: In mineral processing, magnetic separators can help remove unwanted ferrous materials without the use of toxic chemicals, reducing pollution.

4.4 Cost-Effective

Compared to other separation methods, magnetic separation is often cost-effective. It does not require extensive chemical reagents or energy-intensive equipment. Once a magnetic separator is installed, its maintenance costs are typically low, and its operational lifespan is long.

- Example: In the mining industry, magnetic separation allows for the efficient extraction of valuable ores, reducing the need for costly manual labor and expensive chemical processes.

4.5 Safety and Minimal Handling

Magnetic separation provides a safe and efficient way to separate materials with minimal handling. In processes where hazardous materials need to be separated, magnets offer a non-contact method of separation, reducing the risk of injury or exposure.

- Example: In food processing, magnetic separators can be used to remove metal contaminants from food products, ensuring safety for consumers.

The Role of Dry Electromagnetic Separators in Industrial Applications

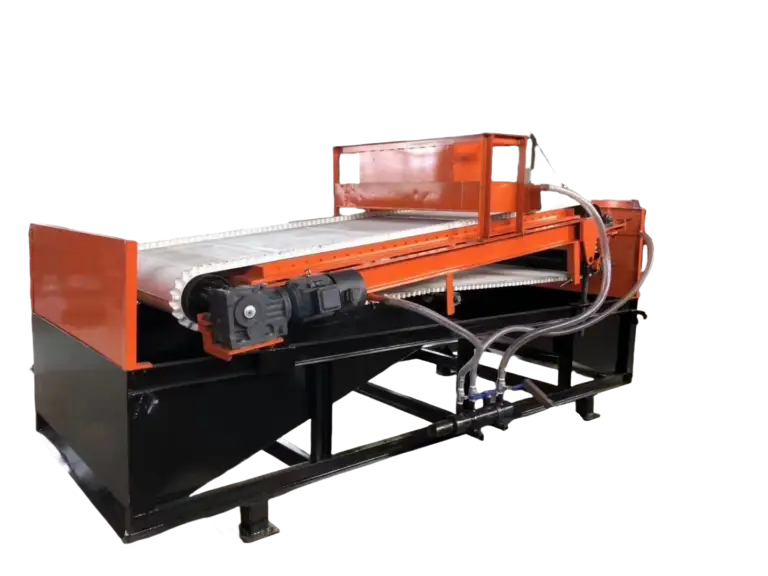

Dry electromagnetic separators, like the Oromineral Dry Electromagnetic Separator, are specialized machines designed for high-efficiency material separation. These separators are primarily used in industries where water is not available or where the materials to be separated are sensitive to moisture.

Features of Dry Electromagnetic Separators:

- Adjustable Magnetic Field: The magnetic field intensity can be adjusted (from 0.5 to 2.0 Tesla) based on the material being processed. This ensures optimal performance for different types of materials.

- High Capacity: These separators can handle large quantities of material (from 5 to 200 tons per hour), making them ideal for large-scale industrial operations.

- Customizable Feed Sizes: The feed size can be adjusted up to 300 mm, allowing for flexibility in different applications.

- Durability: Made from high-quality materials such as stainless steel, cast iron, and alloys, these separators are built to last in demanding industrial environments.

Applications:

Dry electromagnetic separators are used in a variety of industries:

- Mining: To separate valuable ores from non-magnetic materials.

- Recycling: For extracting metals from scrap waste.

- Food Processing: To remove metal contaminants from food products.

- Chemical Industries: For separating ferrous materials from chemicals or powders.

Understanding the ORO Mineral Dry Electromagnetic Separator

The Oromineral Dry Electromagnetic Separator is a high-performance solution designed for efficient and customizable material separation. Here are its key specifications and benefits:

| Parameter | Details |

|---|---|

| Brand | ORO Mineral |

| Model | Customizable (please inquire for specific models) |

| Type | Dry Electromagnetic Separator |

| Capacity | 5-200 t/h (depends on model and material) |

| Feed Size | ≤ 300 mm (adjustable based on application) |

| Magnetic Field Intensity | 0.5-2.0 T (adjustable) |

| Power Consumption | 15-300 kW (depends on model and capacity) |

| Material of Construction | Stainless Steel, Cast Iron, Other Alloys (customizable) |

| Operating Temperature | -20°C to 50°C (depends on model) |

| Dimensions | Customizable (please inquire) |

| Weight | 500 kg – 10,000 kg (depends on model) |

The ORO Mineral separator is ideal for industries that require high throughput and customizable features. With its ability to handle large material volumes and adjust magnetic intensity, it provides excellent performance in diverse applications.

How to Choose the Right Magnetic Separator for Your Needs

When selecting a magnetic separator, it’s important to consider several factors:

- Material Type: Determine the type of material you need to separate (ferrous, non-ferrous, minerals, etc.).

- Capacity: Choose a separator with the appropriate capacity for your operation. Larger operations will need separators with higher throughput.

- Magnetic Field Intensity: Some materials require higher magnetic field intensities for effective separation.

- Customization: Look for a separator that can be customized to suit your specific needs, such as adjustable feed sizes or power options.

FAQs

1. What is the main benefit of using magnets for separation?

The main benefit of using magnets for separation is the ability to efficiently separate ferrous materials from non-ferrous materials without the need for chemicals or extensive manual labor.

2. How does a dry electromagnetic separator work?

A dry electromagnetic separator uses an adjustable magnetic field to attract ferrous materials from a mixture of other substances, separating them based on magnetic properties.

3. Are electromagnetic separators customizable?

Yes, many electromagnetic separators, including the ORO Mineral Dry Electromagnetic Separator, are customizable to suit specific material types, feed sizes, and production capacities.

Conclusion

Magnetic separation is an invaluable tool across multiple industries, offering

high efficiency, versatility, and environmental benefits. With technologies like dry electromagnetic separators, companies can achieve precise and high-capacity material separation, improving product quality and operational efficiency. By understanding the advantages and choosing the right equipment, industries can take full advantage of the power of magnets in separation.