Sand Washing Machine Design Services

ORO Mineral Co., Ltd. is a large-scale intelligent manufacturer specializing in mineral processing, screening, and sand washing equipment. Since its founding in 2014, ORO Mineral has been dedicated to advancing the technology of mineral screening, solid waste recycling, beneficiation, and washing systems. Through continuous innovation, ORO has become a trusted global supplier in mining, construction, and infrastructure sectors.

Table of Contents

- Introduction to Sand Washing Machine Design

- Importance of Professional Design Services

- Types of Sand Washing Machines

- Main Features and Components

- Applications Across Industries

- Sand Washing System Design Process

- Customization and Engineering Support

- Why Choose ORO Mineral Co., Ltd.?

- Summary Table

- FAQs

- References

Introduction to Sand Washing Machine Design

The sand washing machine is an essential piece of equipment for removing impurities such as dust, silt, and clay from sand and gravel. It ensures the production of high-quality construction materials with consistent grain size and cleanliness. Designing a sand washing machine involves engineering considerations related to water flow, sediment control, mechanical strength, and environmental efficiency.

At ORO Mineral Co., Ltd., the focus is on intelligent, high-capacity, and long-lasting sand washing systems. The company’s design services are tailored for diverse operational environments, from small-scale quarry sites to large mining and mineral processing plants.

Importance of Professional Design Services

Designing a sand washing system is more than assembling mechanical parts — it requires engineering expertise, fluid mechanics understanding, and process optimization. Professional design ensures that your washing plant operates efficiently, conserves resources, and meets strict quality and environmental standards.

Key Benefits of Expert Design:

- Optimized water circulation and sedimentation control.

- Improved sand cleanliness and grading accuracy.

- Reduced energy consumption and maintenance costs.

- Extended equipment lifespan and reduced downtime.

- Compliance with environmental and industrial safety regulations.

Types of Sand Washing Machines

ORO Mineral manufactures two main types of sand washing machines designed for high performance and long service life:

1. Spiral Sand Washing Machine

- Heavy-duty construction and large capacity (up to 100 tons/hour).

- Ideal for natural sand, crushed stone, and various ores.

- Equipped with a continuous spiral raking system for efficient sediment removal.

- Simple structure, reliable operation, and easy maintenance.

2. Wheel-Based Sand Washing Machine

- Compact design with low power consumption.

- Best suited for fine sand recovery and concrete applications.

- Less water consumption and easier installation compared to spiral designs.

- Ideal for small to medium-scale operations.

Both designs are available with customizable configurations depending on capacity requirements, feed material, and site layout.

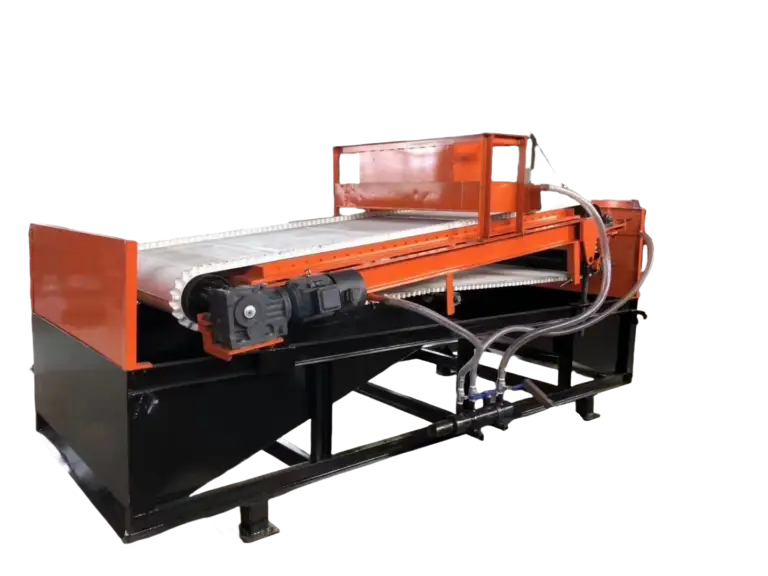

Main Features and Components

ORO Mineral’s sand washing machines are engineered for durability, efficiency, and versatility. Each model integrates several innovative features that enhance performance and reduce operational costs.

- Heavy-Duty Frame: Built from high-grade steel for long-term durability.

- Self-Contained Spiral Lifting Device: Simplifies installation and maintenance.

- Continuous Raking Mechanism: Ensures even sediment discharge.

- High Classification Efficiency: Achieved through optimized weir height and spiral geometry.

- Adjustable Tank Design: Customizable to different materials and processes.

- Low Maintenance: Rugged components with easy access points for cleaning and repairs.

Applications Across Industries

Sand washing systems are critical in multiple industrial sectors. ORO Mineral’s machines are deployed across diverse environments for material recovery, product purification, and waste management.

Common Applications:

- Mining and Mineral Processing: Cleaning and classifying ores and minerals.

- Construction and Infrastructure: Producing high-grade sand for concrete and asphalt.

- Recycling Plants: Recovering usable sand from demolition or construction waste.

- Stone Crushing Plants: Removing dust and clay from crushed aggregates.

- Metal Dressing and Beneficiation: Classification and dehydration of metal ores.

Sand Washing System Design Process

ORO Mineral’s design process combines technical innovation with site-specific customization. Each project begins with a detailed assessment of material characteristics, production targets, and environmental conditions.

Steps in the Design Process:

- 1. Project Assessment: Analyzing raw material type, feed size, and moisture content.

- 2. Process Simulation: Using software to model water flow, sedimentation, and throughput.

- 3. Equipment Configuration: Selecting optimal machine type (spiral or wheel) and layout.

- 4. Structural Design: Engineering tank geometry, spiral pitch, and drive power.

- 5. Environmental Integration: Designing for water recycling, noise control, and waste reduction.

- 6. On-Site Installation: Supervised setup with operator training and calibration.

The result is a high-performance washing system that ensures clean sand output, minimal water loss, and consistent product quality.

Customization and Engineering Support

Every project has unique requirements. That’s why ORO Mineral offers fully customized sand washing machine design services. Their engineers collaborate closely with clients to create solutions that align with specific material properties, production goals, and operational constraints.

Customization Options:

- Adjustable tank and spiral dimensions.

- Variable-speed drives for energy optimization.

- Anti-wear coatings and corrosion-resistant materials.

- Integration with screening, crushing, and recycling systems.

- Automated control systems with real-time monitoring.

In addition, ORO provides after-sales support, spare parts supply, and remote technical assistance to ensure long-term operational success.

Why Choose ORO Mineral Co., Ltd.?

With more than a decade of expertise, ORO Mineral Co., Ltd. has become a global leader in sand washing and mineral processing solutions. The company’s dedication to innovation, quality, and customer satisfaction sets it apart from competitors.

Our Competitive Advantages:

- Full In-House Production: From R&D to manufacturing and quality control.

- Advanced Technology: Integration of intelligent controls and energy-efficient systems.

- Comprehensive Support: End-to-end project management and on-site training.

- Global Reach: Serving industries in Asia, Europe, Africa, and South America.

- Trusted Performance: Proven results in large-scale infrastructure and mining projects.

Product Portfolio:

- Sand Washing Machine (Spiral & Wheel Type)

- Screening and Classification Equipment

- Solid Waste Recycling Systems

- Ore Beneficiation and Separation Machinery

By choosing ORO Mineral, clients gain access to integrated design services, durable machinery, and a commitment to continuous improvement.

Summary Table

| Aspect | Details |

|---|---|

| Machine Types | Spiral and Wheel-Based Sand Washing Machines |

| Handling Capacity | 1 – 100 TPH |

| Suitable Materials | Natural sand, crushed stone, gravel, manufactured sand, and ores |

| Key Features | Heavy-duty structure, spiral lifting system, low maintenance, customizable tank design |

| Industry Applications | Mining, metallurgy, construction, road building, recycling |

| Manufacturer Highlight | ORO Mineral Co., Ltd. — Advanced sand washing and mineral processing expert |

Frequently Asked Questions (FAQs)

1. What capacity options are available for ORO’s sand washing machines?

ORO offers washing systems with capacities from 1 to 100 tons per hour, suitable for both small and large-scale production.

2. How do I choose between spiral and wheel-type washers?

Spiral designs are ideal for heavy-duty and high-capacity operations, while wheel-based models are better suited for fine sand recovery and lower energy consumption.

3. Do you offer on-site setup and training?

Yes. ORO provides on-site installation support, equipment calibration, and operator training for every project.

4. Can the sand washing system be integrated with existing production lines?

Absolutely. ORO engineers specialize in custom integration with crushing, screening, and recycling systems to create complete processing solutions.

References