How Much Does a Sand Washer Plant Cost in 2025?

Table of Contents

- Introduction

- Key Factors That Affect Sand Washer Plant Cost

- Types of Sand Washing Plants and Their Price Range

- Applications of Sand Washer Plants

- Spotlight: ORO Mineral Sand Washing Machine 100 TPH

- Estimated Cost Breakdown in 2025

- Tips to Reduce Installation & Maintenance Costs

- Summary Table

- References

Introduction to Sand Washer Plant Cost

In 2025, demand for sand washer plants continues to grow as industries like construction, quarrying, and mining expand globally. The cost of setting up a sand washer plant depends on several factors such as production capacity, plant design, and after-sales service. This guide provides a detailed look at the average price range, cost drivers, and key considerations before investing in a sand washing system.

Key Factors That Affect Sand Washer Plant Cost

Understanding what drives cost can help businesses choose the right equipment and avoid unnecessary overspending. Here are the primary cost drivers:

- Plant Capacity: The higher the tons per hour (TPH), the higher the initial investment. Small plants (10–30 TPH) are cheaper compared to 100+ TPH setups.

- Machine Type: Spiral sand washers tend to be more expensive than wheel-based designs due to higher efficiency and durability.

- Material Type: Plants handling abrasive materials (quartz, granite) require more durable components, slightly increasing costs.

- Automation Level: Fully automated plants with PLC control systems cost more but save labor in the long run.

- Location & Logistics: Freight, customs clearance, and installation costs vary by region and add to total investment.

- After-Sales Service: Suppliers offering on-site setup, spare parts, and training often charge a premium but ensure better uptime.

Types of Sand Washing Plants and Their Price Range

1. Wheel-Based Sand Washer Plants

Wheel washers are popular for light to medium-duty applications. They are simple, compact, and energy-efficient.

- Typical Price Range: $15,000 – $40,000 (10–50 TPH capacity)

- Best For: Manufactured sand, quarry fines, construction sand cleaning.

- Advantages: Low maintenance, lower water consumption, easy installation.

2. Spiral Sand Washer Plants

Spiral designs are used for heavy-duty, continuous operations and can handle high TPH capacities with excellent classification efficiency.

- Typical Price Range: $35,000 – $120,000 (30–100+ TPH capacity)

- Best For: Mining, ore treatment, large-scale infrastructure projects.

- Advantages: High cleaning efficiency, longer lifespan, customizable tank design.

3. Combined Sand Washing & Recycling Plants

These integrated systems wash, recover fines, and recycle water — making them eco-friendly.

- Typical Price Range: $50,000 – $200,000 depending on complexity.

- Best For: Operations where water recycling is critical.

- Advantages: Minimal water loss, maximized sand recovery, reduced environmental impact.

Applications of Sand Washer Plants

Sand washer plants are crucial for multiple industries where clean and graded sand is a must:

- Construction & Infrastructure: Ensures quality sand for concrete, road base, and bricks.

- Mining & Ore Processing: Removes impurities and enhances mineral recovery.

- Quarrying: Reduces dust, clay, and fines in crushed stone aggregates.

- Environmental Projects: Used for soil remediation and wastewater treatment.

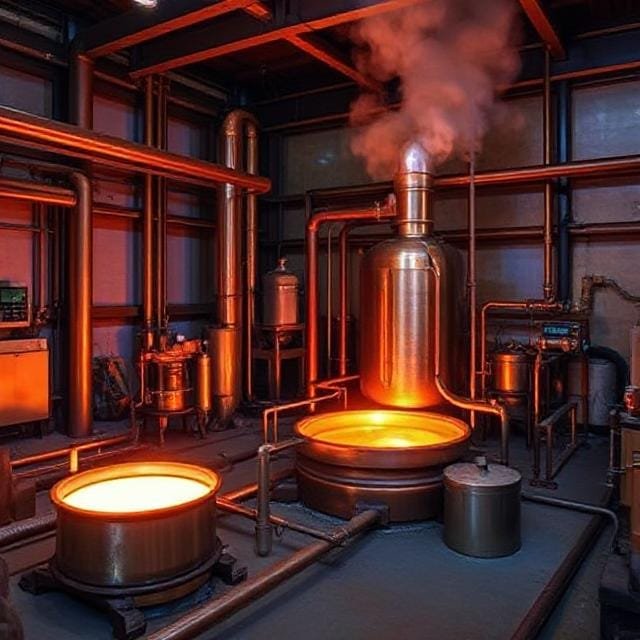

Spotlight: ORO Mineral Sand Washing Machine 100 TPH

Oromineral Sand Washing Machine stands out in 2025 with its high capacity and robust design, suitable for both small and large-scale operations.

- Handling Capacity: From 1 up to 100 tons per hour

- Available Models: Spiral and wheel-based designs

- Industry Applications: Mining, quarrying, infrastructure, concrete cleaning

- Main Features:

- Heavy-duty construction with long service life

- Powerful self-contained spiral lifting device

- Continuous spiral raking system

- High classification efficiency with low maintenance

- Customizable tank and weir height design

- Support & Services: Tailored system design, on-site setup assistance, and full project solutions.

Estimated Cost Breakdown in 2025

Below is an approximate cost breakdown for a mid-sized sand washer plant (50–100 TPH):

- Equipment Purchase: $45,000 – $90,000

- Transportation & Customs: $3,000 – $10,000 (varies by region)

- Installation & Commissioning: $5,000 – $15,000

- Electrical & Piping Setup: $4,000 – $12,000

- Annual Maintenance: ~$2,000 – $5,000

- Total Estimated Investment: $60,000 – $130,000 depending on options and location.

Tips to Reduce Installation & Maintenance Costs

- Choose a Local Supplier: Minimizes freight and customs costs.

- Opt for Energy-Efficient Designs: Saves operational expenses over time.

- Bundle Equipment: Buying a complete plant package can lower per-unit cost.

- Plan for Scalability: Choose modular designs that allow capacity upgrades without full replacement.

- Schedule Regular Maintenance: Preventive care reduces downtime and costly repairs.

Summary Table

| Plant Type | Typical Capacity | Estimated Cost (2025) | Best For |

|---|---|---|---|

| Wheel-Based Sand Washer | 10–50 TPH | $15,000 – $40,000 | Construction sand cleaning, small operations |

| Spiral Sand Washer | 30–100+ TPH | $35,000 – $120,000 | Mining, heavy-duty applications |

| Combined Washing & Recycling | 30–100+ TPH | $50,000 – $200,000 | Water-scarce regions, eco-friendly projects |

| Installation & Setup | — | $5,000 – $15,000 | Depends on plant size & location |