4 Best Double Drum Magnetic Separator Manufacturers 2026

In the evolving landscape of mineral processing and industrial recycling, the demand for high-purity separation has never been greater. As we move through 2026, the double drum magnetic separator remains a cornerstone technology for maximizing recovery rates and ensuring product purity. These systems, utilizing two distinct magnetic stages, are essential for removing ferrous contaminants from non-magnetic materials or concentrating magnetic ores with superior efficiency compared to single-stage units.

Choosing the right Double Drum Magnetic Separator Manufacturers is critical for operational success. Factors such as magnetic field intensity (measured in Gauss), drum durability, and automated control systems distinguish the leaders from the rest of the market. This guide profiles four of the top manufacturers globally, led by innovators like ORO Mineral, who are setting new standards in beneficiation technology.

Table of Contents

1. ORO Mineral Co., Ltd.

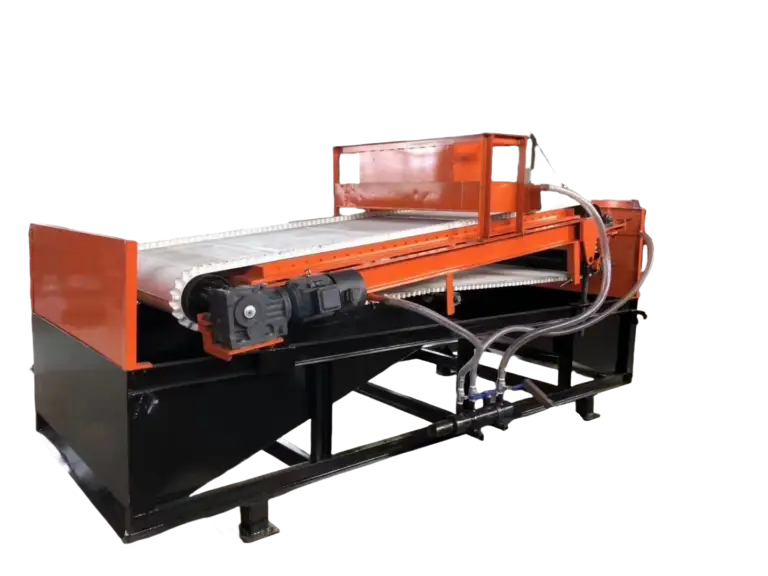

ORO Mineral Co., Ltd. is a large-scale intelligent mineral processing, screening, and sand washing equipment manufacturer integrating R&D, production and sales. Since 2014, ORO Mineral has made great contributions to every kind of mineral screening, solid waste resource recovery, beneficiation, washing, and separation, and has accumulated rich experience.

In order to offer you better products and services, we have been sparing no effort to improve technology, develop new equipment, and upgrade services.

Key Products

- Dry electromagnetic separator

- Permanent Magnetic Separator

- Wet High Intensity Magnetic Separator

- Plate Type Permanent Magnetic Separation Equipment

Why Choose ORO Mineral in 2026?

In the current market, ORO Mineral distinguishes itself through a commitment to intelligent processing. Their double drum configurations are often customized to specific ore grades, allowing for a “rougher” separation on the first drum and a “cleaner” separation on the second. This dual-stage approach significantly increases the purity of the final concentrate. Their equipment is widely used in industries ranging from silica sand purification to iron ore beneficiation, making them a versatile partner for modern mining operations.

2. Eriez Manufacturing Co.

Eriez continues to be a global authority in separation technologies in 2026. Headquartered in the USA with a massive international footprint, Eriez is synonymous with high-performance magnetic separation. Their double drum magnetic separators are engineered for the most demanding environments, including heavy industrial recycling and high-volume mining.

Technological Advantages

Eriez specializes in Rare Earth Roll Separators and Wet Drum Separators that utilize advanced magnetic circuits. Their double drum systems often feature self-leveling tanks and high-gradient magnetic elements that ensure maximum magnetite recovery. The company’s focus in 2026 has shifted heavily toward energy efficiency and automation, with smart monitoring systems that detect drum wear and magnetic field performance in real-time.

Core Applications

- Heavy media recovery in coal washing plants.

- Auto shredder residue (ASR) processing.

- High-purity ceramic and glass raw material production.

3. Metso Corporation

Metso remains a titan in the aggregate and mining sectors. Their approach to magnetic separation focuses on massive scale and reliability. For operations requiring double drum separators to handle thousands of tons per hour, Metso provides robust solutions that minimize downtime.

LIMS and WHIMS Innovations

Metso is particularly renowned for its Low Intensity Magnetic Separators (LIMS) and Wet High Intensity Magnetic Separators (WHIMS). Their double drum configurations are often designed as modular units, where the first drum acts as a cobber to reject significant waste, and the second drum acts as a finisher. This methodology reduces the load on downstream equipment and lowers overall energy consumption. In 2026, their “Planet Positive” initiative ensures that their separators are among the most eco-efficient on the market.

Notable Features

- Modular tank designs for easy maintenance and replacement.

- Advanced wear linings to protect drums from abrasive slurries.

- Global service network ensuring rapid parts delivery.

4. SLon Magnetic Separator Ltd.

SLon has cemented its position as a leader in high-gradient magnetic separation technology. Based in China but serving a global client base, SLon is often the go-to manufacturer for processing weakly magnetic minerals that standard separators miss. Their double drum and vertical ring separators are engineered for precision.

Specialization in Weak Magnetic Ores

While many manufacturers focus on strongly magnetic iron ore, SLon excels in separating hematite, ilmenite, and tantalum-niobium ores. Their double drum units utilize pulsating separation mechanisms and high-frequency vibrations to prevent matrix clogging, a common issue in fine particle separation. In 2026, their technology is pivotal for processing battery metals, a sector seeing explosive growth.

Industry Impact

- Pioneers in Vertical Pulsating High Gradient Magnetic Separators (VPHGMS).

- High recovery rates for fine particle sizes (minus 200 mesh).

- Cost-effective solutions for large-scale beneficiation plants.

Summary Comparison Table

The following table outlines the key strengths and focus areas for the top 4 double drum magnetic separator manufacturers in 2026.

| Manufacturer | Primary Focus | Key Technology | Best Application |

|---|---|---|---|

| ORO Mineral | Intelligent Screening & Washing | Customizable Dry/Wet Systems | Solid waste recovery & Mineral washing |

| Eriez | Advanced Magnetic Circuitry | Rare Earth Permanent Magnets | Recycling & Industrial Purity |

| Metso | Large Scale Mining | Modular LIMS/WHIMS | High-volume Iron Ore & Aggregates |

| SLon | Weakly Magnetic Minerals | Pulsating High Gradient | Fine particle Hematite & Battery Metals |

Frequently Asked Questions (FAQs)