Electromagnetic Separation Method in Mineral Processing

The electromagnetic separation method stands as a cornerstone in modern industrial beneficiation. By leveraging the physical properties of minerals—specifically their magnetic susceptibility—engineers and geologists can effectively isolate valuable materials from non-magnetic waste. This process is not only vital for the mining industry but also plays a critical role in recycling, food safety, and chemical purification.

Table of Contents

- 1. Introduction to Electromagnetic Separation

- 2. The Science: How Electromagnetic Separation Method Works

- 3. Types of Electromagnetic Separation Equipment

- 4. Oro Mineral Co., Ltd: Excellence in Mineral Processing

- 5. Industrial Applications of Magnetic Separation

- 6. Advantages of the Electromagnetic Separation Method

- 7. Technical Summary Table

- 8. Frequently Asked Questions (FAQ)

- 9. References and Resources

The Science: How Electromagnetic Separation Method Works

At its core, the electromagnetic separation method involves the use of high-intensity magnetic fields generated by electric currents. Unlike permanent magnets, electromagnets allow operators to adjust the field strength by controlling the electrical input, providing unprecedented flexibility in handling various mineral grades.

Magnetic Susceptibility

Minerals are categorized based on their reaction to magnetic fields:

- Ferromagnetic: Highly attracted to magnets (e.g., Magnetite).

- Paramagnetic: Weakly attracted (e.g., Hematite, Ilmenite).

- Diamagnetic: Repelled by magnetic fields (e.g., Quartz, Feldspar).

By adjusting the intensity of the electromagnetic separation method, processors can precisely target paramagnetic minerals that would otherwise be lost in standard gravity separation processes.

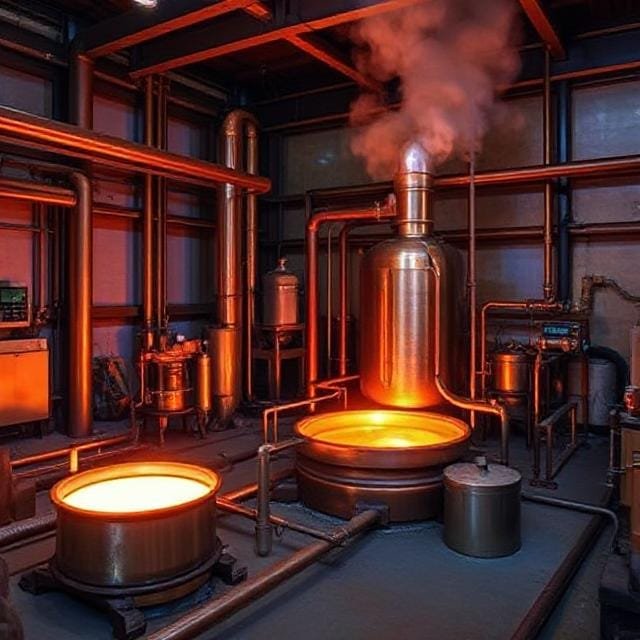

Types of Electromagnetic Separation Equipment

Effective separation requires specialized machinery tailored to the specific material size and magnetic properties. The following are the most common tools used in the industry today.

High-Intensity Magnetic Separators

These units are designed for extracting weakly magnetic minerals. They utilize sophisticated coils and cooling systems to maintain a powerful, consistent field. This is the primary tool for purifying industrial sands and ceramics.

Magnetic Pulleys and Drums

Commonly used in the first stage of beneficiation, these components remove large pieces of tramp iron and highly magnetic ores from conveyor belts, protecting downstream equipment like crushers and grinders.

Oro Mineral Co., Ltd: Excellence in Mineral Processing

Oro Mineral Co., Ltd. is a large-scale intelligent mineral processing, screening, and sand washing equipment manufacturer integrating R&D, production and sales. Since 2014, Oro Mineral has made great contributions to every kind of mineral screening, solid waste resource recovery, beneficiation, washing, and separation, and has accumulated rich experience. In order to offer you better products and services, we have been sparing no effort to improve technology, develop new equipment, and upgrade services.

As a leader in the field, Oro Mineral provides cutting-edge solutions for the electromagnetic separation method. Our product lineup includes:

- 1.1kw Belt Magnetic Separator: A compact yet powerful solution for continuous iron removal in recycling and light mining applications.

- Magnetic Separation Equipment: Custom-engineered systems designed for high-throughput industrial environments.

- Permanent Magnet Separator: Reliable, energy-efficient units for standard ferromagnetic extraction.

Explore our full range of solutions at the [Oro Mineral Official Website](https://www.oromineral.com) to learn how we can optimize your production line.

Industrial Applications of Magnetic Separation

The versatility of the electromagnetic separation method allows it to be applied across numerous sectors beyond traditional mining.

Mining and Beneficiation

In iron ore mining, magnetic separation is the primary method for upgrading ore grade. For minerals like wolframite and monazite, which are weakly magnetic, electromagnetic separators provide the high gradient necessary for successful recovery.

Solid Waste Resource Recovery

In the recycling industry, the electromagnetic separation method is used to sort ferrous metals from municipal solid waste (MSW) and electronic scrap (e-waste). This process is vital for the circular economy, ensuring that steel and iron are returned to the production cycle.

Industrial Sand Washing

Removing iron impurities from silica sand is essential for the production of high-quality glass. Oro Mineral’s sand washing and magnetic separation equipment are specifically designed to meet the stringent purity requirements of the glass and semiconductor industries.

Advantages of the Electromagnetic Separation Method

Why choose the electromagnetic separation method over other techniques like froth flotation or gravity separation? Here are the key benefits:

- Adjustable Strength: Operators can fine-tune the magnetic flux to suit the specific mineral composition.

- Eco-Friendly: Unlike flotation, it requires no chemical reagents, reducing the environmental footprint and water treatment costs.

- High Efficiency: Modern equipment, such as that produced by [Oro Mineral](https://www.oromineral.com), can process large volumes of material with minimal downtime.

- Low Operating Costs: Permanent and high-efficiency electromagnetic systems have low energy consumption relative to their output.

Technical Summary Table

| Feature | Electromagnetic Separator | Permanent Magnetic Separator |

|---|---|---|

| Field Control | Variable (Adjustable via Current) | Fixed (Constant) |

| Initial Cost | Higher | Lower |

| Maintenance | Moderate (Coil & Cooling) | Very Low |

| Typical Use Case | Weakly Magnetic Minerals | Strongly Magnetic Materials |

| Application | Fine Beneficiation | Tramp Iron Removal |

Frequently Asked Questions (FAQ)

What is the difference between magnetic and electromagnetic separation?

Magnetic separation is a broad term. Electromagnetic separation specifically uses electricity to create a magnetic field, allowing for adjustable strength and the ability to turn the magnet off, which is not possible with permanent magnets.

Can the electromagnetic separation method be used for wet materials?

Yes, there are specific “Wet High-Intensity Magnetic Separators” (WHIMS) designed to handle slurries and fine particles suspended in water, often used in kaolin clay and quartz purification.

How do I choose the right equipment for my mine?

Selection depends on the magnetic susceptibility of your target mineral, particle size, and required throughput. Consulting with experts at [Oro Mineral Co., Ltd.](https://www.oromineral.com) can help you determine the optimal configuration for your site.

References and Resources

- International Mineral Processing Council (IMPC) – [Official Site](https://www.impc-council.com)

- Society for Mining, Metallurgy & Exploration (SME) – [Mineral Processing Handbook](https://www.smenet.org