10 Industrial applications of Electromagnetic separator

Electromagnetic separation technology has become essential across modern industries due to its ability to accurately extract, clean, and classify materials based on magnetic properties. With industries becoming increasingly automated and quality-driven, the demand for efficient applications of Electromagnetic separator continues to grow.

This comprehensive guide explores the most important industrial applications, the operational advantages, and a detailed spotlight on one of the most advanced solutions on the market—the Oromineral Dry Electromagnetic Separator.

Table of Contents

Introduction to Electromagnetic Separators

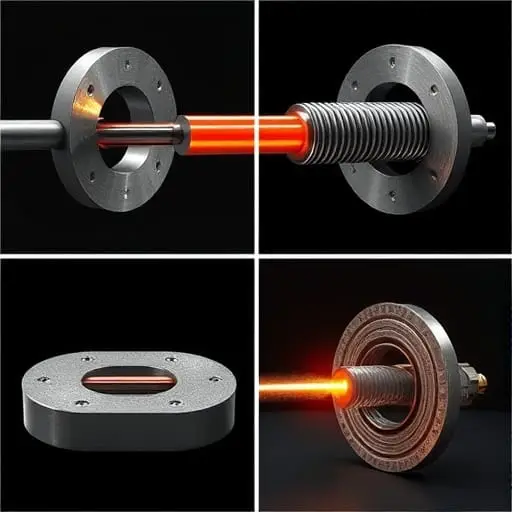

An electromagnetic separator is a precision-engineered industrial machine that uses adjustable magnetic fields to isolate ferromagnetic and paramagnetic particles from non-magnetic material flows. Unlike permanent magnetic separators, electromagnetic models provide variable intensity settings, allowing industries to fine-tune separation performance based on material characteristics.

Because of this flexibility, the applications Electromagnetic separator cover a broad range of industries—including mining, recycling, manufacturing, ceramics, foundries, and raw material processing. This technology ensures cleaner outputs, greater equipment protection, and significantly improved material purity.

How Electromagnetic Separators Work

Electromagnetic separators function by generating a powerful magnetic field using electricity. When material passes through the magnetic zone, ferrous contaminants are attracted and removed, while non-magnetic materials continue through the process.

Core components include:

- Electromagnetic coil

- Magnet housing with cooling system

- Conveyor belt or vibratory feeder

- Collection area for magnetic discharge

- Control panel for magnetic intensity adjustment

Why industries prefer electromagnetic systems:

- Adjustable magnetic field strength for maximum precision

- Higher separation efficiency for fine or weakly magnetic particles

- Ability to handle high-volume material flows

- Durability for harsh industrial environments

Key Industrial Applications of Electromagnetic Separator

Below are the major applications of Electromagnetic separator across modern industries, showcasing how this technology plays a critical role in material purification, equipment protection, and process optimization.

1. Mining Industry: Separation of Magnetic Ores

Mining represents one of the most vital applications. Electromagnetic separators extract magnetic ores—such as magnetite and hematite—from gangue materials to increase ore grade and reduce processing costs.

- Enhances mineral purity

- Reduces waste material volume

- Improves downstream milling efficiency

2. Recycling: Sorting Magnetic Metals from Waste Streams

In recycling facilities, electromagnetic separators help recover valuable ferrous metals from municipal waste, electronic waste, plastics, rubber, and industrial scrap.

- Increases recycling profitability

- Reduces contamination in reusable materials

- Supports sustainability goals

3. Raw Material Processing: Removing Tramp Iron

Many industries—cement, plastics, grain, chemicals, and pharmaceuticals—rely on the technology to remove tramp iron that can damage machinery or compromise product quality.

- Protects crushers and milling equipment

- Ensures product purity

- Prevents costly production downtime

4. Ceramics & Glass Manufacturing

Ceramic and glass industries depend on extremely pure raw materials. Even tiny magnetic particles can cause defects in finished products. Electromagnetic separators ensure high-grade mineral inputs.

- Improves color consistency

- Reduces structural imperfections

- Enhances transparency and strength

5. Foundries: Removing Magnetic Inclusions

Metal foundries use electromagnetic systems to remove metallic impurities from molten metals, sand molds, and casting materials.

- Creates higher-quality castings

- Reduces defects and cracks

- Improves furnace performance

6. Coal Processing

Electromagnetic separators remove magnetic minerals such as pyrite, improving coal combustion efficiency and reducing emissions.

7. Chemical and Pharmaceutical Industries

These industries require extremely fine material purity. Electromagnetic separators remove micron-sized ferrous particles that could contaminate sensitive products.

8. Food Processing & Agriculture

To meet international safety standards, food producers use electromagnetic separation to remove metal fragments from powders, grains, and bulk ingredients.

9. Construction Materials

Sand, gravel, limestone, and cement production benefit from the removal of iron contaminants that weaken structural materials.

10. Metallurgical Processing

Electromagnetic systems refine metals, remove slag residues, and increase the efficiency of thermal and mechanical treatments.

Benefits of Using Electromagnetic Separators

- High-precision separation

- Adjustable magnetic intensity

- Reliable performance in heavy-duty environments

- Protection for downstream machinery

- Improved material purity and product quality

- Low long-term operational cost

Product Spotlight: ORO Mineral — Dry Electromagnetic Separator

The Oromineral Dry Electromagnetic Separator represents one of the most advanced solutions available for dry material separation. It is engineered to meet the demands of mining, recycling, ceramics, raw material processing, and heavy industrial applications.

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand | ORO Mineral |

| Model | Customizable |

| Type | Dry Electromagnetic Separator |

| Capacity | 5–200 t/h |

| Feed Size | ≤ 300 mm |

| Magnetic Field Intensity | 0.5–2.0 T |

| Power Consumption | 15–300 kW |

| Material of Construction | Stainless Steel, Cast Iron, Alloys |

| Operating Temperature | -20°C to 50°C |

| Dimensions | Customizable |

| Weight | 500–10,000 kg |

Applications

- Mining: separation of magnetic ores

- Recycling: sorting magnetic metals

- Raw material protection: tramp iron removal

- Ceramics & glass manufacturing

- Foundries and metal casting processes

Summary Table of Main Applications

| Industry | Application |

|---|---|

| Mining | Extraction of magnetic ores |

| Recycling | Sorting ferrous metals |

| Ceramics | Purification of raw materials |

| Foundries | Removal of metallic inclusions |

| Chemicals | Fine particle purification |

| Food Processing | Metal contamination removal |

| Construction Materials | Impurity removal in aggregates |

| Coal Processing | Elimination of pyrite and iron minerals |

Frequently Asked Questions

1. What materials can an electromagnetic separator process?

It can separate iron, steel, magnetite, pyrite, and any ferrous or weakly magnetic material.

2. How is an electromagnetic separator different from a permanent magnet?

Electromagnetic systems offer adjustable magnetic intensity, making them suitable for complex and variable material flows.

3. Can electromagnetic separators handle fine powders?

Yes—this is one of their major advantages, especially in pharmaceuticals and chemicals.

4. Are dry electromagnetic separators suitable for high-volume production?

Yes, especially advanced models like the Oromineral system designed for heavy-duty operation.

5. Do they require much maintenance?

Maintenance is minimal due to robust construction and stable operating systems.