6 Best Magnetic Separator for Grinding Machines 2025

The Magnetic Separator for grinding machines plays a critical role in industries where metal contamination is a concern. These separators efficiently remove unwanted ferrous materials from granular products, ensuring cleaner output and better performance in the grinding process. Here, we present the 6 best magnetic separators for grinding machines in 2025, designed for high efficiency, easy maintenance, and durability.

Table of Contents

Table of Contents

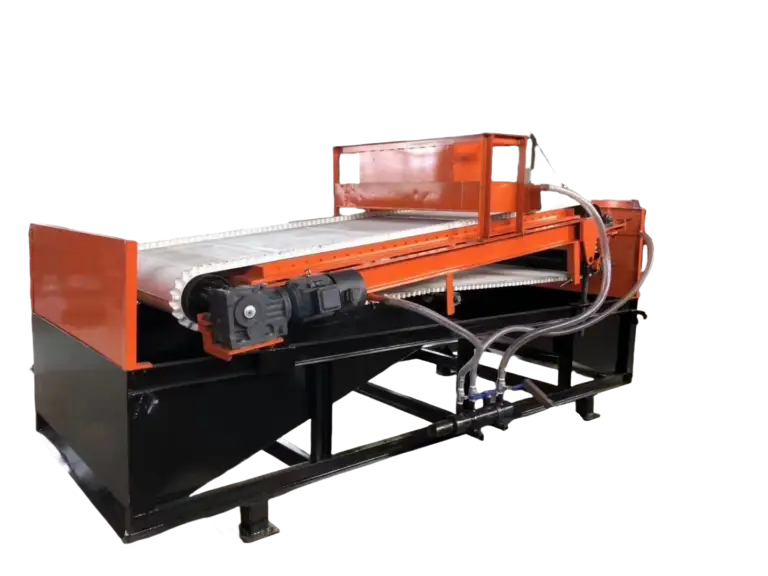

1.1.1kw Belt Magnetic Separator

The 1.1kw Belt Magnetic Separator by Oromineral is designed to offer superior separation capabilities for grinding applications. This model features high-intensity magnetic fields that attract ferrous contaminants from materials moving along the conveyor belt.

- Brand: Oromineral

- Model Number: ZT-1530P

- Place of Origin: Foshan, Guangdong, China

- Certification: ISO9001

- Power Rating: 1.1kw

- Minimum Order Quantity: 1 Set

- Price: Negotiable

- Packaging: Standard Exporting Package

- Delivery Time: Within 25 days after downpayment

- Payment Terms: L/C, T/T

- Supply Ability: 50 sets per month

This magnetic separator is perfect for applications that require high separation efficiency and reliability. The 1.1kw Belt Magnetic Separator is engineered for ease of maintenance and high performance, making it a top choice for grinding machine operations.

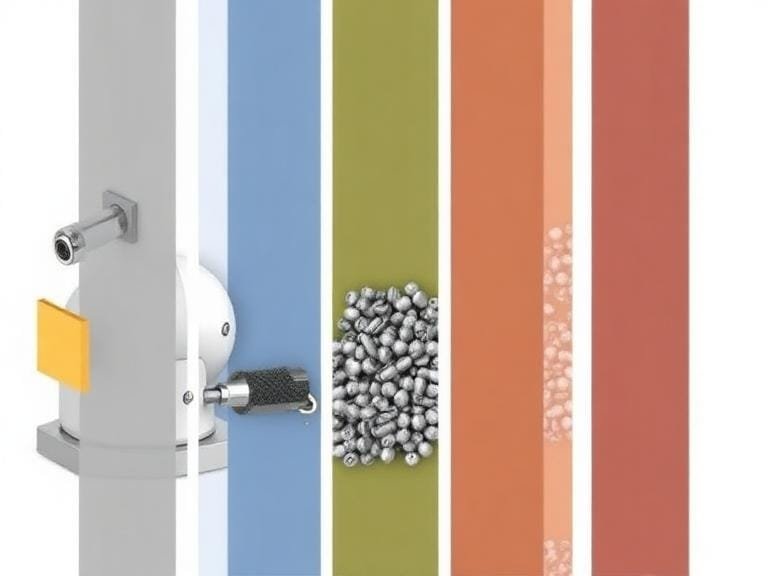

Eddy Current Separator Machine

The Eddy Current Separator Machine by Oromineral is designed for the efficient separation of non-ferrous metals, especially in recycling and mining applications. It features advanced technology to provide superior magnetic separation performance.

- Drum Diameter: Up to 1500mm

- Magnetic Field Intensity: 17-20 GS

- Capacity: 2-5 m³/h (depending on the model)

- Power Rating: 1.1kW to 3kW

- Speed: Adjustable belt and drum speeds for optimal separation

- Models Available: HTECS-3 to HTECS-20

The Eddy Current Separator Machine provides efficient separation of metals in challenging grinding environments, with customizable options to suit various needs.

Electrostatic Separator

Electrostatic Separators are highly effective in separating non-ferrous metals from various materials. These separators are often used in combination with magnetic separators for maximum purity and material recovery in grinding processes.

Overband Magnetic Separator

The Overband Magnetic Separator is designed for the efficient removal of ferrous contaminants from bulk materials, ensuring a clean and consistent feed in grinding machines. Its strong magnetic force makes it ideal for industries handling large volumes of materials.

Wet Drum Magnetic Separator

The Wet Drum Magnetic Separator is ideal for separating fine ferrous particles from slurries and wet material. This separator is particularly useful in applications where the material is in a liquid form or contains water.

High Intensity Magnetic Separator

High Intensity Magnetic Separators are designed to remove weakly magnetic particles in grinding machines. These separators are perfect for applications that demand the highest purity levels, such as pharmaceutical and food industries.

Summary of the Best Magnetic Separators for Grinding Machines

| Separator | Features | Power Rating |

|---|---|---|

| 1.1kw Belt Magnetic Separator | High separation efficiency, reliable, easy maintenance | 1.1 kW |

| Eddy Current Separator Machine | Non-ferrous metal separation, customizable options | 1.1 kW to 3 kW |

| Electrostatic Separator | Ideal for non-ferrous metals, used with magnetic separators | Varies by model |

Frequently Asked Questions

What is a Magnetic Separator for grinding machines?

A magnetic separator is a device that uses a magnetic field to remove ferrous contaminants from materials in grinding machines, improving efficiency and product quality.

How does an Eddy Current Separator work?

An Eddy Current Separator uses a rotating magnetic field to induce currents in non-ferrous metals, separating them from other materials in the grinding process.

What type of industries benefit from Magnetic Separators?

Industries such as recycling, mining, food processing, and pharmaceuticals benefit from magnetic separators, as they ensure cleaner material output and higher purity standards.