5 Steps Involved in Processing Minerals — Practical Guide for Engineers & Managers

This guide explains the 5 steps involved in processing minerals with professional detail and actionable tips. We’ll cover comminution, sizing, concentration, dewatering, and refining — plus a summary table, FAQs, and a company spotlight on ORO Mineral Co., Ltd.

Overview — What the 5 steps involved in processing minerals cover

When professionals talk about the 5 steps involved in processing minerals, they mean the standard flow that transforms mined ore into a marketable product. The typical sequence is:

- Comminution (crushing & grinding)

- Sizing & classification (screens, cyclones)

- Concentration & separation (gravity, magnetic, flotation)

- Dewatering & thickening (filters, thickeners)

- Refining & final treatment (smelting, leaching, polishing)

This article expands each of the 5 steps involved in processing minerals, explains why they matter, and offers pragmatic design and operational notes that reduce cost, increase recovery, and improve product quality.

Step 1 — Comminution (Crushing & Grinding)

The first of the 5 steps involved in processing minerals is comminution: reducing the size of run-of-mine ore to liberate valuable minerals for downstream separation. Comminution consumes the largest share of plant energy and is a major capital and operating cost.

Primary, Secondary, Tertiary Crushing

Primary crushers (jaw, gyratory) reduce large boulders; secondary and tertiary crushers (cone, impact) further reduce particle size. Each stage of comminution in the 5 steps involved in processing minerals must be optimized for throughput, wear life, and energy efficiency.

Grinding Mills and Energy Efficiency

Ball mills, SAG mills and rod mills are used to grind ore to the target liberation size. Since the comminution phase in the 5 steps involved in processing minerals is energy intensive, process engineers often apply energy-saving technologies — e.g., high-pressure grinding rolls (HPGR), staged grinding, and fine pre-screening — to reduce cost per tonne.

Best-practice tips (Comminution)

- Conduct a comminution test program (JK Drop Weight, Bond Ball Mill Work Index) to size equipment accurately.

- Install coarse ore sorting upstream to remove waste and reduce the energy needed in the 5 steps involved in processing minerals.

- Monitor power and throughput closely — small improvements in this first step multiply downstream.

Step 2 — Sizing & Classification

The second of the 5 steps involved in processing minerals is sizing: separating particles by size using hydrocyclones, screens, and classifiers. Correct sizing concentrates liberated particles for the next step and protects downstream equipment.

Screens and Cyclones

Vibrating screens remove oversize particles and de-sand cyclones classify finer fractions. In the sequence of the 5 steps involved in processing minerals, accurate classification helps maximize recovery and reduce over-grinding, which wastes energy and creates slimes.

Hydrocyclone Circuits & Cut-size Control

Cyclone operating point (vortex finder size, feed pressure) sets the cut size. Tuning classification is a pivotal part of controlling the mass balance across the 5 steps involved in processing minerals.

Practical sizing recommendations

- Use staged classification to improve process stability in wet circuits.

- Install on-line particle size analyzers where possible to control the cut size dynamically.

- Reduce slimes formation through controlled grinding rather than aggressive re-circulation.

Step 3 — Concentration & Separation

Central to the 5 steps involved in processing minerals is concentration: the removal of gangue and enrichment of the valuable mineral. Typical methods include gravity separation, magnetic separation, flotation, and electrostatic separation.

Gravity Separation

Gravity methods (spirals, shaking tables, jigs) exploit differences in density. For many ores — e.g., gold, tin, tungsten — gravity concentration is a low-cost, high-recovery step within the 5 steps involved in processing minerals.

Magnetic & Eddy Current Separation

Magnetic separators remove ferrous minerals; eddy current separators separate non-ferrous conductive metals — both are important in the range of technologies used in the 5 steps involved in processing minerals.

Flotation

Flotation is the dominant method for sulfide ores and some industrial minerals. Flotation circuits use reagents, air dispersion, and cell hydraulics to create concentrated froths. In designing the 5 steps involved in processing minerals, flotation control (pH, reagent dosing, pulp density) is often the highest leverage point for improving recovery and grade.

Optimization pointers (Concentration)

- Pilot-scale flotation tests are invaluable when developing the separation step in the 5 steps involved in processing minerals.

- Use staged cleaning and regrinding to reach required concentrate specs while minimizing losses.

- Integrate sensor-based sorting (XRT, optical) to pre-concentrate and reduce downstream load.

Step 4 — Dewatering & Thickening

After concentration, the next of the 5 steps involved in processing minerals is dewatering: removing process water to produce a transportable, saleable concentrate. Efficient dewatering reduces logistics cost and prepares material for refining.

Common Dewatering Equipment

Thickeners, drum filters, filter presses, and centrifuges are commonly used. The choice of equipment in the fourth of the 5 steps involved in processing minerals depends on the slurry rheology, required moisture content, and throughput.

Water Management & Reuse

Managing process water is critical. Recycle reduces freshwater consumption and lowers tailings volume. Effective water recycling is an integral part of modern designs of the 5 steps involved in processing minerals.

Operational tips (Dewatering)

- Use polymer flocculants matched to ore chemistry to speed thickening and improve filter cake quality.

- Monitor cake moisture and adjust press cycles to maintain product specifications.

- Design for modularity — staged dewatering helps manage peak loads and simplifies maintenance.

Step 5 — Refining, Smelting & Final Treatment

The final of the 5 steps involved in processing minerals is refining: converting concentrates into market-ready metal or chemically treated products. Refining can include smelting, roasting, hydrometallurgical leaching, electro-winning, or chemical finishing processes.

Smelting & Pyrometallurgy

For many base metals (copper, nickel, lead), smelting converts concentrates into matte or blister metal followed by refining. In the sequence of the 5 steps involved in processing minerals, smelting is capital and energy intensive but often essential for producing saleable metal.

Hydrometallurgy & Leaching

Leaching (cyanide for gold, sulfuric acid for copper oxide) dissolves metals from concentrate and allows recovery via solvent extraction and electrowinning (SX-EW). Hydrometallurgical routes are frequently used in the modern interpretation of the 5 steps involved in processing minerals, especially for low-grade ores.

Final Product Conditioning

Final steps include drying, sizing, impurity removal and packaging. The last of the 5 steps involved in processing minerals ensures product stability, compliance with buyer specs, and safe transport.

Quality control & traceability

Implementing batch tracking and analytical QA during the final step of the 5 steps involved in processing minerals reduces rejection risk and supports customer acceptance.

Summary table — Quick reference for the 5 steps involved in processing minerals

| Step | Main equipment | Key objective | Operational notes |

|---|---|---|---|

| Comminution | Jaw/ gyratory, cone crushers, SAG/ball mills | Size reduction, liberation | Energy-intensive; optimize to reduce downstream load |

| Sizing & Classification | Screens, hydrocyclones, classifiers | Separate by size, prepare feed for separation | Control cut-size tightly to protect flotation and filters |

| Concentration & Separation | Spiral concentrators, flotation cells, magnetic separators | Enrich valuable minerals, reject gangue | Pilot tests and reagent optimization critical |

| Dewatering & Thickening | Thickeners, filter presses, centrifuges | Remove water, produce transportable concentrate | Polymer selection and cake moisture control matter |

| Refining & Final Treatment | Smelters, leach circuits, SX-EW, furnaces | Produce market-ready metal or chemical product | Strict environmental and quality controls required |

Use this table as a checklist when designing or auditing a plant to ensure each of the 5 steps involved in processing minerals is addressed with technical rigor and cost control.

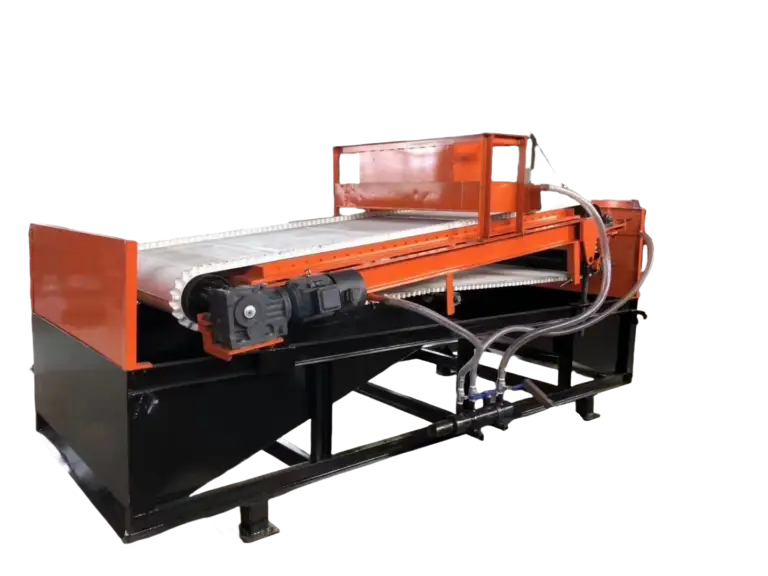

Company spotlight — ORO Mineral Co., Ltd.

ORO Mineral Co., Ltd. is a large-scale intelligent mineral processing, screening, and sand washing equipment manufacturer integrating R&D, production and sales. Since 2014, ORO Mineral has made great contributions to every kind of mineral screening, solid waste resource recovery, beneficiation, washing, and separation, and has accumulated rich experience.

ORO Mineral supplies equipment that directly supports the 5 steps involved in processing minerals, especially the concentration and washing phases. Their product range includes:

- Sand Washing Machine 100 TPH Long Life — ideal for mineral washing and classification

- Gravity Spiral Concentrator — effective for gravity concentration in step three of the 5 steps involved in processing minerals

- 1.1kw Belt Magnetic Separator — supports magnetic separation in the concentration step

- Eddy Current Separator Machine — used to separate non-ferrous metals during concentration

- Gravity Spiral Chute Separator — reliable for low-cost gravity concentration

ORO Mineral combines field-tested equipment with digital control systems — a practical partner for owners implementing efficient versions of the 5 steps involved in processing minerals.