5 Best Drum Type Magnetic Separators 2026: The Ultimate Industrial Guide

In the heavy-duty world of mining, recycling, and material processing, the efficiency of your mineral beneficiation line often rests on a single piece of equipment: the magnetic separator. As we move into 2026, the Best drum type magnetic separators have evolved far beyond simple permanent magnets. They now integrate advanced electromagnetic circuitry, modular maintenance features, and rare-earth materials that can capture even the finest paramagnetic particles.

Choosing the right separator is a strategic decision that affects long-term operational costs, product purity, and equipment protection. From high-capacity wet drum models to precision dry electromagnetic systems, the market in 2026 offers specialized solutions for every industrial challenge. This guide evaluates the top five systems currently leading the industry in innovation and reliability.

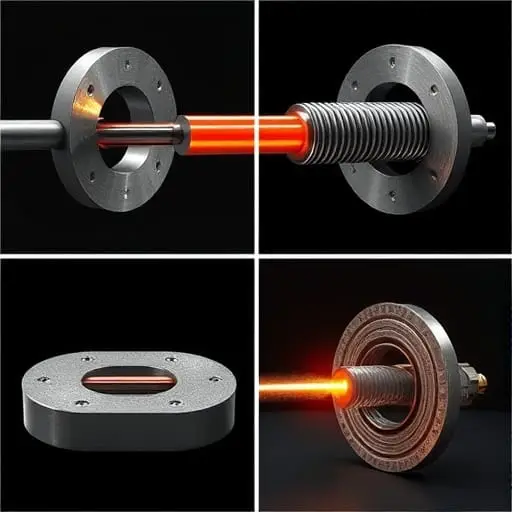

1. Oromineral Dry Electromagnetic Separator

Featured Product: Oromineral Dry Electromagnetic Separator

The ORO Mineral Dry Electromagnetic Separator is a cornerstone for modern ore processing and slag recycling. Designed for versatility, it is one of the Best drum type magnetic separators for environments where precise control over magnetic field intensity is required to separate varying grades of magnetic material.

Key Features:

- High Separation Efficiency: Advanced electromagnetic system provides precise separation of magnetic materials.

- Durability: Constructed with robust materials to withstand heavy-duty applications and harsh environments.

- Energy-Efficient: Optimized design minimizes power consumption, reducing operational costs.

- Easy Maintenance: Modular design allows for quick and simple maintenance and repairs.

- Versatile Applications: Suitable for a wide range of materials including ores, slags, and recycled materials.

| Parameter | Specification |

|---|---|

| Brand | ORO Mineral |

| Type | Dry Electromagnetic Separator |

| Capacity | 5-200 t/h (Customizable) |

| Feed Size | ≤ 300 mm (Adjustable) |

| Magnetic Field Intensity | 0.5-2.0 T (Adjustable) |

| Power Consumption | 15-300 kW |

| Construction | Stainless Steel, Cast Iron, Alloys |

| Weight | 500 kg – 10,000 kg |

2. Eriez P-Series Wet Drum Separators

Eriez has long been a global standard-bearer in magnetic technology. In 2026, their P-Series wet drum separators are recognized as some of the Best drum type magnetic separators for heavy media recovery and iron ore concentration. These units utilize a sophisticated 750-gauss interpole magnetic element, which has set the benchmark for magnetite recovery in the mining sector.

A standout feature of the Eriez 2026 lineup is the use of high-energy rare-earth magnets that allow for a smaller physical footprint while maintaining higher magnetic flux gradients. Their tank designs—available in concurrent and counter-rotation styles—ensure that processed slurry spends maximum time in the scavenging zone, yielding recovery rates of 99.9% or higher.

3. Steinert MT Series Magnetic Drums

Steinert’s MT series represents the peak of German engineering in the sorting industry. These magnetic drums are particularly prized in the recycling sector for their extreme robustness. Whether processing incinerator bottom ash or shredded electronic scrap, the MT series uses an eccentric pole system that concentrates magnetic force exactly where the material discharge occurs.

By 2026, Steinert has optimized their “extracting” operation mode, where the drum rotates against the supply flow. This configuration is widely considered the Best drum type magnetic separators setup for achieving high-purity ferrous fractions from contaminated waste streams. Their self-cleaning effect, triggered by a polarity change at the splitter point, prevents film and fine particles from clogging the drum surface.

4. Goudsmit Neoflux® Drum Separators

Goudsmit Magnetics, based in the Netherlands, has focused heavily on the food and pharmaceutical sectors for 2026. Their Neoflux® drum separators are equipped with Neodymium (NdFeB) magnets that can capture stainless steel wear particles as small as 0.03 mm. This level of precision makes them the Best drum type magnetic separators for protecting downstream grinding and mixing machinery in food production.

The 2026 models feature a hygienically finished housing that eliminates stagnation points where product could build up. With magnetic field depths reaching up to 100mm and flux densities of 3000 to 8000 gauss, Goudsmit systems offer a continuous cleaning cycle that doesn’t require production stops, providing a seamless solution for high-volume free-fall pipelines.

5. Kanetec KDS High-Power Series

Japan’s Kanetec continues to lead the Asian market with the KDS series. These units are specifically designed for compact installation in existing plant layouts. In 2026, the KDS-HE series offers a field strength of 500 mT (5000 Gauss), which is exceptionally high for a compact permanent magnet drum.

The Kanetec KDS is frequently cited as the Best drum type magnetic separators choice for relocation-heavy industries, such as mobile crushing units and temporary recycling sites. Their motor-driven systems are enclosed in light-weight yet durable casings, offering an “out-of-the-box” solution for removing bolts, iron pieces, and other tramp metal from hopper-fed raw materials.

Summary Specification Table: 5 Best Drum Type Magnetic Separators 2026

| Model / Brand | Primary Application | Magnet Type | Intensity Range | Max Capacity |

|---|---|---|---|---|

| Oromineral Dry | Mining & Slag | Electromagnetic | 0.5 – 2.0 Tesla | 200 t/h |

| Eriez P-Series | Heavy Media Recovery | Rare Earth / Ferrite | 750 – 1000 Gauss | 99.9% Recovery |

| Steinert MT | Metal Recycling | Permanent / Electro | High Gradient | 3,400 mm Width |

| Goudsmit Neoflux | Food & Pharma | Neodymium | 3000 – 8000 Gauss | 120 m³/h |

| Kanetec KDS | Tramp Iron Removal | Permanent | 1800 – 5000 Gauss | Compact / Mobile |

How to Choose the Best Drum Type Magnetic Separator

Selecting the Best drum type magnetic separators for your facility requires a multi-faceted approach. In 2026, experts recommend focusing on three core criteria: Material Particle Size, Magnetic Susceptibility, and the Processing Environment.

1. Particle Size and Volume

For large rocks and slag (up to 300mm), the robust Oromineral Dry electromagnetic separator is ideal due to its massive construction and adjustable intensity. Conversely, for fine powders in the food industry, a high-gradient Neodymium drum like the Goudsmit Neoflux is necessary to capture microscopic contaminants.

2. Wet vs. Dry Processing

If your process involves liquids or sludges, a wet drum separator (like Eriez) is essential. These systems use tanks to manage the slurry flow and ensure the magnetic particles are effectively lifted out of the liquid medium. For dry granulates, sand, or shredded scrap, the Best drum type magnetic separators are dry-type units that rely on gravity and drum rotation to shed non-magnetic waste.

3. Field Intensity Requirements

Highly magnetic materials (iron, magnetite) only require Low-Intensity Magnetic Separators (LIMS). However, as ore grades decline in 2026, many mines are dealing with weakly magnetic minerals like hematite or pyrrhotite. These require High-Intensity Magnetic Separators (HIMS) or electromagnetic systems that can reach intensities up to 2.0 Tesla.

Frequently Asked Questions

References

1. ORO Mineral Technical Catalog 2026. “Dry Electromagnetic Separation Systems: Efficiency and Customization.”

2. Steinert Global Sorting Systems. “Magnetic Drum Robustness and Pole Configuration Study.”