4 Types of magnetic separation in mining

In the ever-evolving landscape of the global extractive industry, efficiency and sustainability have become the dual pillars of success. As we move into 2026, the demand for high-purity minerals has skyrocketed, driven by the green energy transition and the need for rare earth elements. At the heart of this mineral processing revolution is a fundamental physical process: magnetic separation. Understanding the various applications of magnetic separation in mining is essential for any modern operation seeking to maximize recovery rates and reduce environmental impact.Magnetic separation is a process in which magnetically susceptible material is extracted from a mixture using a magnetic force. This technique is indispensable for the separation of iron ore, the purification of non-metallic minerals, and the recovery of valuable metals from industrial waste. With advancements in superconducting magnets and intelligent automation, the precision of these systems has reached unprecedented levels.

Table of Contents

- 1. The Fundamentals of Magnetic Separation in Mining

- 2. Partner Spotlight: ORO Mineral Co., Ltd.

- 3. Type 1: Low-Intensity Magnetic Separation (LIMS)

- 4. Type 2: High-Intensity Magnetic Separation (HIMS)

- 5. Type 3: High-Gradient Magnetic Separation (HGMS)

- 6. Type 4: Wet vs. Dry Magnetic Separation Techniques

- 7. Comparison of Separation Equipment Performance

- 8. Frequently Asked Questions (FAQs)

- 9. Academic References and Industry Standards

1. The Fundamentals of Magnetic Separation in Mining

The core principle of magnetic separation in mining involves the difference in magnetic susceptibility between ore minerals and gangue minerals. In a processing circuit, feed material is passed through a magnetic field. Magnetic particles are attracted to the magnet and separated from the non-magnetic stream. This is a purely physical process, meaning it does not require the heavy chemical reagents used in flotation, making it one of the most eco-friendly beneficiation methods available today.

Mineral susceptibility is generally classified into three categories: ferromagnetic (strongly attracted, like magnetite), paramagnetic (weakly attracted, like hematite or ilmenite), and diamagnetic (repelled, like quartz or feldspar). By fine-tuning the magnetic flux density, engineers can target specific minerals within a complex ore body. In 2026, the integration of IoT sensors into these machines allows for real-time adjustments to magnetic strength, optimizing recovery as the ore grade fluctuates during mining operations.

ORO Mineral Co., Ltd.: Excellence in Mineral Processing

ORO Mineral Co., Ltd. is a large-scale intelligent mineral processing, screening, and sand washing equipment manufacturer integrating R&D, production, and sales. Since 2014, ORO Mineral has made great contributions to every kind of mineral screening, solid waste resource recovery, beneficiation, washing, and separation, and has accumulated rich experience.

In order to offer you better products and services, we have been sparing no effort to improve technology, develop new equipment, and upgrade services. Our commitment to innovation ensures that we provide the mining industry with the most robust and efficient magnetic separation in mining solutions available globally.

Featured High-Performance Equipment:

- Dry electromagnetic separator: Optimized for fine-grained dry ore purification.

- Plate Type Permanent Magnetic Separation Equipment: High-reliability separation for industrial sand and non-metallic minerals.

- Wet High Intensity Magnetic Separator (WHIMS): The gold standard for recovering weakly magnetic minerals in slurry form.

3. Type 1: Low-Intensity Magnetic Separation (LIMS)

Low-Intensity Magnetic Separation (LIMS) is primarily used for the recovery of ferromagnetic minerals, most notably magnetite ($Fe_3O_4$). These systems typically operate with a magnetic field strength of less than 0.3 Tesla (3,000 Gauss). Because magnetite is highly magnetic, it does not require a massive energy input to be pulled from the gangue.

LIMS equipment often takes the form of magnetic drums. As the ore pulp or dry crushed rock passes over the rotating drum, the magnetite sticks to the surface, while the waste falls away. LIMS is highly cost-effective and is used as a primary separation stage to remove the bulk of the iron before more expensive processing steps. In 2026, the use of rare-earth permanent magnets in LIMS has significantly reduced the electricity consumption of these units compared to older electromagnetic designs.

4. Type 2: High-Intensity Magnetic Separation (HIMS)

High-Intensity Magnetic Separation (HIMS) is designed to capture paramagnetic minerals that LIMS would miss. This includes minerals like hematite, siderite, and manganese ores. These machines generate much stronger magnetic fields, often ranging from 0.8 to 2.0 Tesla (8,000 to 20,000 Gauss).

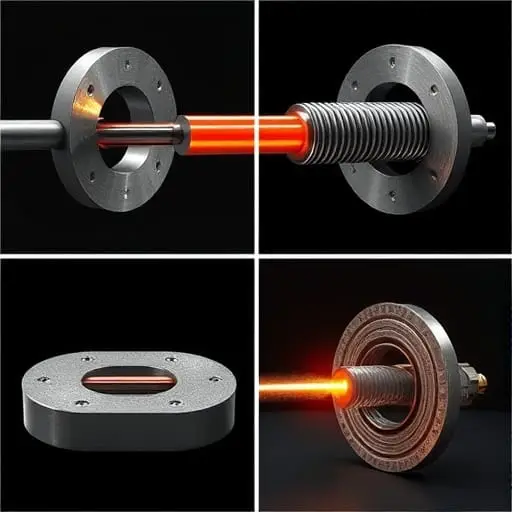

One of the most effective HIMS solutions is the Plate Type Permanent Magnetic Separation Equipment. These systems use high-performance neodymium magnet arrays to create a deep magnetic field that can penetrate a thick layer of material on a conveyor. This type of magnetic separation in mining is vital for the glass and ceramics industry, where even a tiny speck of iron contamination can ruin the final product. HIMS is also increasingly used in the recycling sector to separate stainless steel and other weakly magnetic alloys from shredded electronics.

5. Type 3: High-Gradient Magnetic Separation (HGMS)

High-Gradient Magnetic Separation (HGMS) represents the pinnacle of magnetic separation in mining technology. It is used for the finest particles (often less than 75 microns) and the weakest magnetic susceptibilities. The “gradient” refers to the change in magnetic field strength over a very short distance. By placing a magnetic matrix—such as steel wool or expanded metal—inside a powerful magnetic field, the intensity is concentrated at the sharp edges of the matrix.

HGMS is particularly useful for kaolin clay purification and the removal of iron from industrial minerals. In 2026, superconducting HGMS units have become more common in high-value mining operations, allowing for field strengths of up to 5 Tesla. This technology allows for the recovery of microscopic particles of rare earth elements that were previously considered lost in tailing ponds.

6. Type 4: Wet vs. Dry Magnetic Separation Techniques

The choice between wet and dry magnetic separation in mining is usually determined by the grain size of the ore and the downstream processing requirements. Each has distinct advantages and requires specific equipment like the Dry electromagnetic separator or the Wet High Intensity Magnetic Separator.

Dry Magnetic Separation

Dry separation is preferred for coarse materials and in regions where water is scarce. It eliminates the need for drying the final concentrate, which saves a massive amount of energy. However, dry systems struggle with fine dust, as the particles tend to clump together due to electrostatic forces, masking the magnetic properties. Advanced dry electromagnetic separators solve this by using vibration and air-fluidization to keep particles separated as they enter the magnetic zone.

Wet Magnetic Separation

Wet separation uses water as a transport medium. This allows for the processing of much finer particles, as the water breaks up clumps and allows the magnets to act on individual grains. Wet systems, such as the Wet High Intensity Magnetic Separator (WHIMS), are the industry standard for high-purity iron ore and mineral sands. The water also helps to wash away non-magnetic slimes, resulting in a much cleaner final product.

7. Comparison of Separation Equipment Performance

| Equipment Type | Magnetic Strength | Best Mineral Type | Processing State |

|---|---|---|---|

| LIMS Drum Separator | 0.1 – 0.3 Tesla | Magnetite, Pyrrhotite | Wet or Dry |

| Plate Type Permanent | 0.5 – 1.2 Tesla | Ilmenite, Garnet | Dry (Conveyor) |

| Dry Electromagnetic | 1.0 – 1.5 Tesla | Fine iron removal | Dry (Fine powder) |

| Wet High Intensity (WHIMS) | 1.0 – 2.0 Tesla | Hematite, Wolframite | Wet (Slurry) |

| Superconducting HGMS | 2.0 – 5.0 Tesla | Rare Earths, Kaolin | Wet |

8. Frequently Asked Questions (FAQs)

Why is magnetic separation in mining considered “Green”?

Unlike froth flotation, which uses complex chemicals and surfactants that can be toxic to local ecosystems, magnetic separation is a purely physical process. It uses natural magnetic forces to separate minerals, reducing the chemical footprint of the mine and making tailing management much simpler and safer.

How do I choose between a permanent magnet and an electromagnet?

Permanent magnets (like those in ORO Mineral’s Plate Type equipment) require no power to maintain their field, making them extremely cost-effective and reliable. Electromagnets, however, allow you to adjust the field strength on the fly and can be turned off to easily release captured magnetic material, which is useful for highly automated “self-cleaning” cycles.

Can magnetic separation be used for gold mining?

Gold itself is diamagnetic (not attracted to magnets). However, magnetic separation is frequently used in gold mining to remove “black sand” (magnetite and ilmenite) from the gold concentrates. This makes the subsequent gravity separation or smelting much more efficient.

What is the impact of particle size on magnetic separation?

Generally, as particle size decreases, the force of gravity and friction becomes less significant compared to surface forces. For very fine particles (sub-20 microns), wet high-gradient systems are required to overcome these surface forces and ensure the magnet can actually “grab” the particle from the fluid stream.

9. Academic References and Industry Standards

- Journal of Mineral Processing: “Advances in Superconducting Magnetic Separation for Fine Mineral Recovery.” (2025).

- International Mining Association: “Standardized Testing Protocols for Magnetic Susceptibility in Complex Ores.“